-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

inserting rock bits techniques and strategies for efficient ...

Inserting Rock Bits Techniques and Strategies for Efficient Drilling

In the realm of drilling operations, the efficiency of rock bits plays a crucial role in determining the success of both the speed and cost-effectiveness of projects. As industries increasingly seek to optimize extraction processes, understanding the techniques and strategies for inserting rock bits effectively becomes paramount.

Rock bits, used primarily for penetrating various geological formations, come in several types, such as roller-cone bits and fixed-cutter bits. Each type has its unique advantages and applications, often dictated by the conditions of the drilling environment. For instance, roller-cone bits are typically employed in softer formations, whereas fixed-cutter bits might be more suitable for harder materials. Choosing the appropriate rock bit is the first step towards ensuring efficient drilling.

One vital technique for inserting rock bits is the correct deployment of drilling parameters. These parameters include weight on bit, rotation speed, and mud circulation rate. Optimizing these factors can significantly enhance penetration rates and bit longevity. For example, applying too much weight on the bit can lead to premature wear or even bit failure, while insufficient weight may result in ineffective penetration. Therefore, gradual adjustments and real-time monitoring are essential for achieving the ideal balance.

inserting rock bits techniques and strategies for efficient ...

In addition to parameter optimization, understanding geological formations is key to successful drilling. Before inserting a rock bit, conducting thorough geological surveys can provide insights into the type of rock, its hardness, and any potential challenges. Armed with this information, operators can select the most suitable bit and adjust their drilling strategy accordingly. Employing advanced technologies, such as seismic surveys and 3D modeling, can facilitate better planning and execution of drilling operations.

Another critical strategy involves continuous monitoring and feedback during the drilling process. Utilizing automated systems and sensors allows for real-time data collection related to bit performance. This information can inform immediate adjustments to drilling practices, enhancing both efficiency and safety. Additionally, incorporating predictive maintenance strategies ensures that bit replacement or repairs occur proactively, minimizing downtime and maximizing productivity.

Training and skill development of personnel cannot be overlooked in the quest for efficient drilling. Operators must be well-versed in the latest techniques for inserting and managing rock bits. This knowledge can significantly impact the overall success of drilling projects, as skilled operators are better equipped to troubleshoot issues and optimize operations.

In conclusion, efficiently inserting rock bits is a multifaceted endeavor that requires a comprehensive understanding of various techniques and strategies. By focusing on optimal drilling parameters, conducting thorough geological assessments, implementing monitoring systems, and investing in personnel training, the drilling industry can continue to improve its efficiency and effectiveness. As technological advancements continue to reshape the landscape of drilling operations, staying abreast of these strategies will be essential for maintaining a competitive edge and ensuring sustainable practices in resource extraction.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

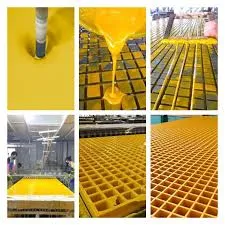

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025