-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

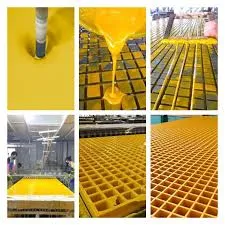

insulated frp covers

Insulated FRP Covers Enhancing Efficiency and Safety

In today’s industrial landscape, the need for safety, efficiency, and durability in manufacturing processes is more crucial than ever. One material that has gained significant attention in recent years is Fiber Reinforced Polymer (FRP), especially when it comes to protective covers. Insulated FRP covers are increasingly being utilized across various sectors, providing a combination of thermal insulation, lightweight properties, and corrosion resistance.

Understanding FRP and Its Benefits

FRP is a composite material made from a polymer matrix reinforced with fibers, commonly glass, carbon, or aramid. This combination results in a product that is not only strong but also lightweight and versatile. The unique properties of FRP include resistance to extreme environmental conditions, making it an ideal choice for outdoor and harsh industrial settings.

Insulated FRP covers incorporate thermal insulation materials within the FRP structure, significantly enhancing their functionality. One of the primary benefits of these covers is their ability to regulate temperature. In industries where temperature control is critical—such as food processing, pharmaceuticals, and chemical manufacturing—insulated FRP covers help maintain consistent internal temperatures. This is essential not just for product quality but also for energy efficiency, as regulated environments reduce the need for excessive heating or cooling.

Energy Efficiency and Cost Savings

The implementation of insulated FRP covers can lead to substantial cost savings. By reducing energy consumption required for temperature regulation, companies can lower their operational costs. Furthermore, these covers minimize heat loss during colder months, which can be crucial for processes that require specific temperature ranges. The energy efficiency gained through the use of insulated FRP covers can also contribute to a company’s sustainability goals, decreasing their overall carbon footprint.

insulated frp covers

Safety and Compliance

In addition to energy efficiency, insulated FRP covers enhance safety in the workplace. By insulation against extreme temperatures, both hot and cold processes become safer for workers. Insulated covers prevent the risk of burns or frostbite from exposure to extreme temperatures, ensuring a safer working environment. Moreover, insulated FRP covers often comply with various industry regulations regarding safety and environmental impact, making them a reliable choice for companies looking to meet compliance standards.

Durability and Longevity

Another noteworthy aspect of insulated FRP covers is their durability. Unlike traditional materials like metal or wood, FRP does not corrode, rot, or degrade over time, even when exposed to harsh chemicals or environmental conditions. This longevity means that manufacturers can rely on insulated FRP covers for extended periods, reducing the need for frequent replacements and the associated costs.

Conclusion

As industries continue to seek ways to improve efficiency, safety, and sustainability, insulated FRP covers stand out as an excellent choice. Their combination of thermal insulation, lightweight properties, and resistance to corrosion and environmental stressors make them an invaluable asset in various applications. By investing in insulated FRP covers, companies can not only enhance their operational efficiency but also create a safer, more sustainable working environment for their employees. As technology advances and new materials are developed, the future for insulated FRP covers looks promising, incorporating even more innovative solutions for industry challenges.