-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Operational Use of Jackhammer Drilling Rods in Construction Projects

The Operation of Jackhammer Drilling Rods A Comprehensive Overview

Jackhammer drilling rods are vital components in construction and mining operations, enabling the effective penetration of tough substrates like concrete, rock, and other dense materials. This article delves into their operational mechanisms, applications, and the best practices for maximizing efficacy and safety.

Understanding Jackhammer Drilling Rods

At its core, a jackhammer is a pneumatic or electric tool that combines a hammer and a chisel to break through hard surfaces. The drilling rod, a crucial extension of the jackhammer, transfers the energy generated by the tool to the surface being worked on. These rods are typically made from high-strength steel to withstand the intense forces during operation.

The operational principles of jackhammer drilling rods hinge upon the effective conversion of pneumatic pressure or electrical energy into a rapid, forceful impact. The rod acts as a conduit for this energy, enabling it to travel efficiently from the hammer mechanism to the drill bit, thereby facilitating effective drilling and breaking actions.

Types of Jackhammer Drilling Rods

There are several types of drilling rods, each designed for specific tasks. The most common types include

1. D-handle and T-handle rods These rods provide a comfortable grip for operators, allowing for increased maneuverability and control. They are often used in environments requiring extended operation durations. 2. Chisel and pointed rods These are specialized for different applications; chisel rods are ideal for breaking up concrete, while pointed rods can penetrate harder rock formations.

3. Extension rods These are used to increase the reach of the jackhammer, allowing the operator to work on deeper or hard-to-reach surfaces.

Applications of Jackhammer Drilling Rods

The versatility of jackhammer drilling rods means they find applications across a broad spectrum of industries

- Construction In construction sites, jackhammers equipped with drilling rods are indispensable for tasks such as breaking up old asphalt, removing concrete slabs, and creating trenches

.jackhammer drilling rod in operation

- Mining Mining operations utilize jackhammers for surface and underground drilling. The rods enable miners to break rock efficiently, allowing for the extraction of valuable minerals.

- Demolition During demolition projects, the combination of jackhammers and drilling rods makes it easier to dismantle buildings safely and effectively.

Best Practices for Using Jackhammer Drilling Rods

Proper handling of jackhammer drilling rods is essential to ensure safety and maximize efficiency. Here are some best practices

1. Training and Certification Operators should undergo comprehensive training to understand the mechanics of jackhammers and the correct handling of drilling rods. Proper training minimizes the risk of accidents and enhances productivity.

2. Regular Maintenance Like any other tool, jackhammers and their rods require regular maintenance. Inspect the rods for any signs of wear or damage, as this can affect drilling efficiency and safety.

3. Use the Right Rod for the Job Selecting the appropriate rod type for the material being drilled is crucial. Using the wrong rod can lead to ineffective drilling and increased wear on the equipment.

4. Wear Protective Gear Safety equipment, including ear protection, goggles, and gloves, should always be worn during operation. The noise levels from a jackhammer can be damaging to hearing, and flying debris can pose a risk to the eyes.

5. Follow Manufacturer Guidelines Each jackhammer comes with specific operational guidelines and safety instructions provided by the manufacturer. Adhering to these recommendations helps in avoiding malfunctions and accidents.

Conclusion

Jackhammer drilling rods are a cornerstone of effective drilling operations in various fields. Understanding their functionality, selecting the appropriate type for the job, and adhering to safety protocols can significantly enhance their performance. By employing best practices in training, maintenance, and operation, professionals can ensure sustainable and efficient use of this powerful tool in their respective industries. As technology advances, we can expect further innovations in drilling rod designs, leading to even greater efficiencies and capabilities in the future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

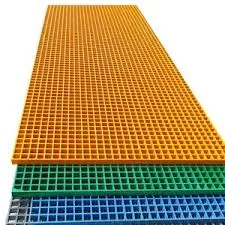

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025