-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 14, 2025 10:26

Back to list

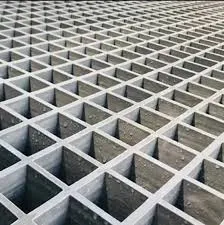

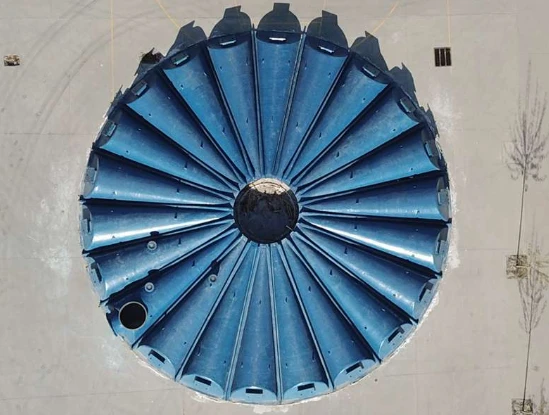

Large Size Field Tanks

Fiberglass products have become an essential component in both thermal and nuclear power sectors. Over recent years, their unique properties have increasingly placed them in the spotlight as industries strive for efficiency, cost-effectiveness, and safety. With a legacy deeply rooted in innovative material science, fiberglass offers unparalleled benefits for power plant applications, emphasizing Experience, Expertise, Authoritativeness, and Trustworthiness.

Adding to its credentials, fiberglass is lauded for its environmental sustainability—a critical consideration in power generation. Fiberglass products are not just effective; their manufacture and application significantly reduce carbon footprints compared to traditional materials. Power plants embracing these advanced materials demonstrate not only an investment in efficient technology but also a commitment to environmental stewardship. This aspect enhances the trustworthiness of power producers as they navigate regulatory landscapes increasingly focused on sustainability. Authoritative voices in the power generation industry, from engineers to environmental scientists, consistently endorse fiberglass products. These endorsements are grounded in rigorous testing and field applications, validating fiberglass’s suitability for modern-day challenges. Peer-reviewed studies further emphasize its advantages, lending academic credibility to its use. Trustworthiness is further compounded by manufacturers who adhere to stringent quality control measures and international standards in fiberglass production. These standards ensure that irrespective of geography, power plants receive consistent, high-quality materials tested for the most demanding conditions. This reliability builds confidence not only among plant operators but also among stakeholders and the general public. In conclusion, the experience of implementing fiberglass products in thermal and nuclear power applications showcases numerous benefits—efficiency, safety, and sustainability. As the global energy landscape evolves, these products stand as pivotal resources, helping power plants meet the dual demands of performance and environmental responsibility. Leveraging their unique properties and supported by authoritative endorsements and rigorous standards, fiberglass products remain at the forefront of power generation innovation.

Adding to its credentials, fiberglass is lauded for its environmental sustainability—a critical consideration in power generation. Fiberglass products are not just effective; their manufacture and application significantly reduce carbon footprints compared to traditional materials. Power plants embracing these advanced materials demonstrate not only an investment in efficient technology but also a commitment to environmental stewardship. This aspect enhances the trustworthiness of power producers as they navigate regulatory landscapes increasingly focused on sustainability. Authoritative voices in the power generation industry, from engineers to environmental scientists, consistently endorse fiberglass products. These endorsements are grounded in rigorous testing and field applications, validating fiberglass’s suitability for modern-day challenges. Peer-reviewed studies further emphasize its advantages, lending academic credibility to its use. Trustworthiness is further compounded by manufacturers who adhere to stringent quality control measures and international standards in fiberglass production. These standards ensure that irrespective of geography, power plants receive consistent, high-quality materials tested for the most demanding conditions. This reliability builds confidence not only among plant operators but also among stakeholders and the general public. In conclusion, the experience of implementing fiberglass products in thermal and nuclear power applications showcases numerous benefits—efficiency, safety, and sustainability. As the global energy landscape evolves, these products stand as pivotal resources, helping power plants meet the dual demands of performance and environmental responsibility. Leveraging their unique properties and supported by authoritative endorsements and rigorous standards, fiberglass products remain at the forefront of power generation innovation.

Next:

Related Products