-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring Extensions for Mining Rock Rod Applications and Techniques

Mining Rock Extension Rods Enhancing Efficiency in Mineral Extraction

Mining is one of the most essential industries in the world, providing the raw materials needed for various sectors, from construction to technology. Among the many components that contribute to the effectiveness of mining operations, rock extension rods play a significant role. These tools are essential in the extraction of minerals from deep underground, enhancing the efficiency and safety of mining processes.

Rock extension rods, also known as drill rods or extension tubes, are cylindrical tools used to extend the reach of drill bits into the earth. Their primary function is to connect a drill bit to a drilling rig, allowing for deep penetration into rock formations. This is crucial in mining operations, where the depth of mineral deposits often requires extensive drilling. The use of these rods not only increases the reach of drilling equipment but also helps in stabilizing the drill bit, leading to more precise and efficient drilling.

Mining Rock Extension Rods Enhancing Efficiency in Mineral Extraction

Moreover, rock extension rods come in various lengths and diameters, offering flexibility for different mining applications. This versatility allows mining operators to customize their drilling equipment based on the specific requirements of a project. For example, deeper mining operations may require longer rods to access mineral deposits located further underground. Conversely, shallower mines may only need shorter rods. This customization is essential for optimizing drilling operations and ensuring the efficient extraction of resources.

mining rock extension rod

The advancements in technology have also significantly improved the design and functionality of rock extension rods. Innovations in manufacturing processes have led to the production of lighter and more robust rods that can be easily handled by mining crews. These technological improvements have made it possible to fabricate rods that are not only efficient but also easier to transport and install, streamlining the overall mining process.

Additionally, incorporating advanced materials and coatings can enhance the performance of rock extension rods. For instance, the application of specialized coatings can reduce wear and tear, increasing the lifespan of the rods. This means fewer replacements are needed, ultimately resulting in lower operational costs. Furthermore, some modern rods are designed to be compatible with various drilling techniques, making them suitable for different mining environments and conditions.

Safety is another critical aspect of mining operations, and using reliable rock extension rods contributes to a safer working environment. When drill bits become stuck in rock formations, it can present significant hazards to workers. High-quality extension rods reduce the risk of accidents by providing stable and reliable drilling capabilities. Additionally, their strength and durability minimize the chances of equipment failure, further ensuring the safety of mining operations.

In conclusion, rock extension rods play a pivotal role in the mining industry by enhancing the efficiency, safety, and efficacy of mineral extraction. Their durability, versatility, and adaptability make them indispensable tools for mining operations of all sizes. As technology continues to advance, we can expect further improvements in the design and performance of these essential components, ultimately leading to more productive and safe mining practices. The future of mining relies not only on innovative techniques but also on robust tools like rock extension rods that facilitate the sustainable extraction of resources crucial for modern society.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

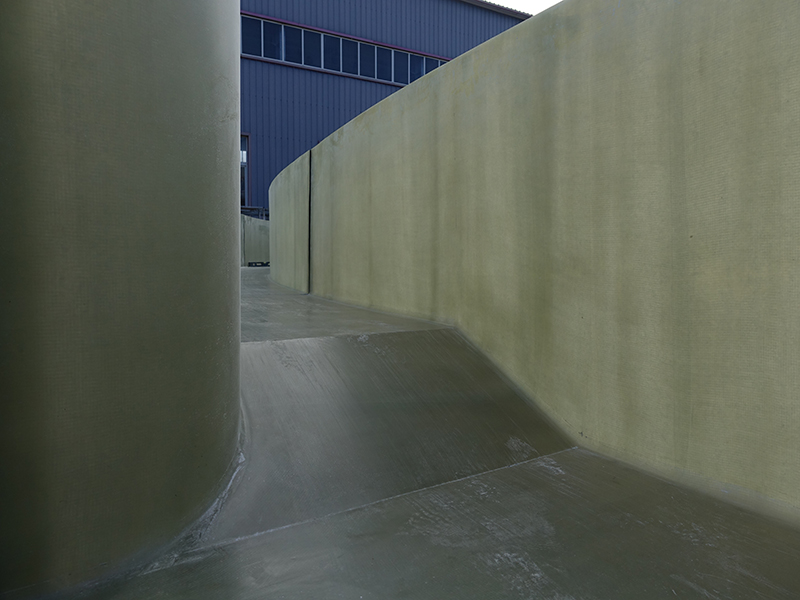

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025