-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 07, 2025 05:52

Back to list

Ladders & Handrails

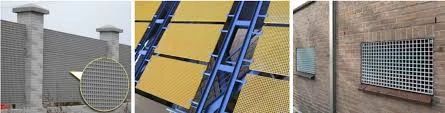

Molded fiberglass grating is an exceptional product that stands out in the realm of industrial flooring solutions, known for its versatility, strength, and durability. Its unique construction, made from high-strength fiberglass and resin, results in a lightweight yet robust grating system that delivers unparalleled performance in diverse environments.

In terms of environmental impact, molded fiberglass grating is an eco-friendly alternative. During its production, fewer natural resources are consumed compared to traditional metal options. Additionally, its long life cycle reduces the frequency of replacement, consequently minimizing environmental waste. As industries increasingly focus on sustainable practices, choosing molded fiberglass grating aligns with these goals, promoting an eco-conscious approach to industrial flooring solutions. Industry standards and certifications further bolster the credibility of molded fiberglass grating. Many manufacturers ensure that their products meet strict quality control measures, adhere to international safety standards, and possess the necessary certifications to guarantee performance and reliability. For professionals aiming to specify materials that contribute to the overall quality and safety of a project, these accolades offer peace of mind and demonstrate authority in the field of industrial installations. Real-world applications illustrate the transformative effect of switching to molded fiberglass grating. In a case study involving a wastewater treatment facility, the switch from metal to fiberglass grating not only extended the lifespan of the flooring system by over 30 percent but also reduced maintenance downtime by half. Employees reported a noticeable improvement in grip on walkways, leading to fewer accidents and an overall enhanced working environment. Such empirical evidence underscores the product's capability to meet and exceed performance expectations in demanding environments. When evaluating engineered flooring solutions, molded fiberglass grating emerges as a top contender, combining strength, safety, and longevity. Its resistance to environmental factors, coupled with ease of customization and environmentally friendly credentials, positions it as a forward-thinking choice for industries committed to innovation and sustainability. For decision-makers in sectors ranging from industrial manufacturing to marine engineering, the implementation of molded fiberglass grating represents not just a product selection, but a strategic enhancement to operational efficiency and safety standards.

In terms of environmental impact, molded fiberglass grating is an eco-friendly alternative. During its production, fewer natural resources are consumed compared to traditional metal options. Additionally, its long life cycle reduces the frequency of replacement, consequently minimizing environmental waste. As industries increasingly focus on sustainable practices, choosing molded fiberglass grating aligns with these goals, promoting an eco-conscious approach to industrial flooring solutions. Industry standards and certifications further bolster the credibility of molded fiberglass grating. Many manufacturers ensure that their products meet strict quality control measures, adhere to international safety standards, and possess the necessary certifications to guarantee performance and reliability. For professionals aiming to specify materials that contribute to the overall quality and safety of a project, these accolades offer peace of mind and demonstrate authority in the field of industrial installations. Real-world applications illustrate the transformative effect of switching to molded fiberglass grating. In a case study involving a wastewater treatment facility, the switch from metal to fiberglass grating not only extended the lifespan of the flooring system by over 30 percent but also reduced maintenance downtime by half. Employees reported a noticeable improvement in grip on walkways, leading to fewer accidents and an overall enhanced working environment. Such empirical evidence underscores the product's capability to meet and exceed performance expectations in demanding environments. When evaluating engineered flooring solutions, molded fiberglass grating emerges as a top contender, combining strength, safety, and longevity. Its resistance to environmental factors, coupled with ease of customization and environmentally friendly credentials, positions it as a forward-thinking choice for industries committed to innovation and sustainability. For decision-makers in sectors ranging from industrial manufacturing to marine engineering, the implementation of molded fiberglass grating represents not just a product selection, but a strategic enhancement to operational efficiency and safety standards.

Related Products