-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

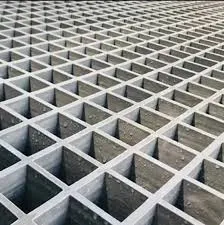

molded grating

Understanding Molded Grating Applications and Benefits

Molded grating is a versatile structural component widely used in various industries due to its unique properties, including strength, durability, and lightweight design. Manufactured from fiberglass reinforced plastic (FRP), molded grating is primarily utilized in environments that require resistance to corrosion, chemical exposure, and extreme weather conditions. This article delves into the features, applications, and benefits of molded grating, showcasing why it has become an essential element in modern construction and industrial processes.

The production of molded grating begins with the combination of fiberglass, resin, and a hardening agent. This process involves a molding technique that allows for the creation of panels with varying thickness levels and mesh sizes. The resulting grating is typically non-slip, minimizing the risk of accidents in slippery conditions. Moreover, the open mesh design promotes excellent drainage and airflow, making it suitable for wet environments. These attributes make it a favored choice in applications ranging from walkways and platforms to drainage systems and machine covers.

One of the standout characteristics of molded grating is its impressive resistance to corrosion. In industries like chemical processing, wastewater treatment, and marine applications, equipment and materials are often exposed to harsh chemicals and saline environments. Traditional steel grating tends to rust and corrode over time under these conditions, leading to increased maintenance costs and potential safety hazards. In contrast, molded grating maintains its structural integrity much longer, reducing downtime and enhancing operational efficiency.

In addition to its corrosion-resistant qualities, molded grating is also remarkably lightweight compared to traditional metal counterparts. This aspect simplifies transportation, installation, and handling. Workers can easily maneuver molded grating panels, which can be especially beneficial in applications where time and safety are critical. Furthermore, the lightweight nature of FRP means that less structural support is required, allowing for more flexible design options and cost savings in construction projects.

molded grating

Molded grating also stands out for its fire resistance. The materials used in its production are inherently non-combustible or have low flammability, making it an appropriate choice for industries that must adhere to stringent safety standards. Facilities like power plants, refineries, and manufacturing units can utilize molded grating without fear of fire hazards, ensuring the safety of workers and the integrity of the equipment.

The aesthetic appeal of molded grating cannot be overlooked either. Available in various colors and finishes, it can easily blend into different environments or provide a pop of color where desired. This adaptability is particularly advantageous in commercial spaces, where aesthetics are often as important as functionality.

In terms of maintenance, molded grating is a low-maintenance option. Unlike metal grating, which may require regular inspections and painting to prevent corrosion, molded grating usually only needs periodic cleaning to remove dirt and debris. Its surface retains its quality over time, contributing to lower long-term costs related to upkeep.

In summary, molded grating represents a practical solution for numerous industrial and commercial applications. Its strength, lightweight nature, corrosion resistance, fire safety features, and aesthetic versatility make it an increasingly popular choice in today’s construction and operational environments. As industries continue to evolve and seek materials that address both functional and safety concerns, molded grating is poised to maintain its relevance and importance in the global marketplace. Embracing this innovative material can lead to enhanced safety, reduced costs, and improved efficiencies for businesses across multiple sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025