-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 04, 2025 06:09

Back to list

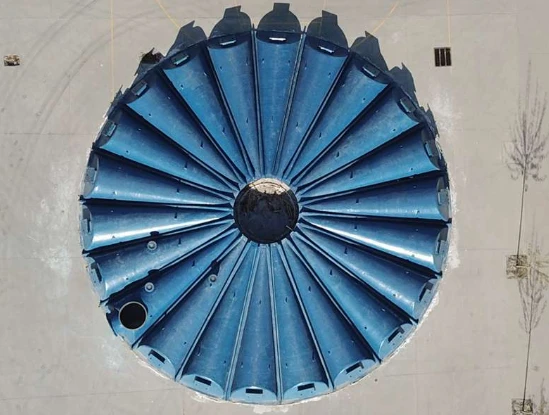

Scrubbers

PVC FRP pipe systems are becoming increasingly integral in various industrial applications, owing to their exceptional properties and versatility. These pipes, constructed from a composite of polyvinyl chloride (PVC) and fiberglass reinforced plastic (FRP), offer numerous advantages that make them an ideal choice for both modern construction and industrial projects.

PVC FRP pipes also represent a significant step forward in terms of environmental sustainability. They require less energy to produce compared to steel or concrete pipes, reducing their carbon footprint. Moreover, these pipes are recyclable, thereby aligning with global efforts towards sustainable construction practices. Authorities in environmental management acknowledge the role of these materials in promoting eco-friendly industrial projects. From a technical standpoint, the versatility of PVC FRP pipes is unmatched. Whether used in sewage systems, chemical drainages, or potable water applications, these pipes adapt effectively due to their customizable properties. Manufacturers and engineers often collaborate to tailor these pipes to specific pressure requirements or environmental conditions, illustrating the expertise harnessed in optimizing these products for best outcomes. Finally, the cost-effectiveness of PVC FRP pipes ensures that they remain an attractive option for industries worldwide. The low maintenance costs, combined with their long service life and reduced energy requirements for production and operation, deliver an excellent return on investment. Businesses have acknowledged cost reductions not only in the immediate installation phase but throughout the lifecycle of the piping system. In conclusion, PVC FRP pipes are revolutionizing the piping industry with their superior performance characteristics. Their adoption across various industries is driven by tangible benefits experienced firsthand, backed by the expertise of manufacturers and engineers who continue to push the boundaries in design and application. The trust placed in PVC FRP piping solutions is well-founded, as they consistently meet and exceed industry expectations.

PVC FRP pipes also represent a significant step forward in terms of environmental sustainability. They require less energy to produce compared to steel or concrete pipes, reducing their carbon footprint. Moreover, these pipes are recyclable, thereby aligning with global efforts towards sustainable construction practices. Authorities in environmental management acknowledge the role of these materials in promoting eco-friendly industrial projects. From a technical standpoint, the versatility of PVC FRP pipes is unmatched. Whether used in sewage systems, chemical drainages, or potable water applications, these pipes adapt effectively due to their customizable properties. Manufacturers and engineers often collaborate to tailor these pipes to specific pressure requirements or environmental conditions, illustrating the expertise harnessed in optimizing these products for best outcomes. Finally, the cost-effectiveness of PVC FRP pipes ensures that they remain an attractive option for industries worldwide. The low maintenance costs, combined with their long service life and reduced energy requirements for production and operation, deliver an excellent return on investment. Businesses have acknowledged cost reductions not only in the immediate installation phase but throughout the lifecycle of the piping system. In conclusion, PVC FRP pipes are revolutionizing the piping industry with their superior performance characteristics. Their adoption across various industries is driven by tangible benefits experienced firsthand, backed by the expertise of manufacturers and engineers who continue to push the boundaries in design and application. The trust placed in PVC FRP piping solutions is well-founded, as they consistently meet and exceed industry expectations.

Next:

Related Products