-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

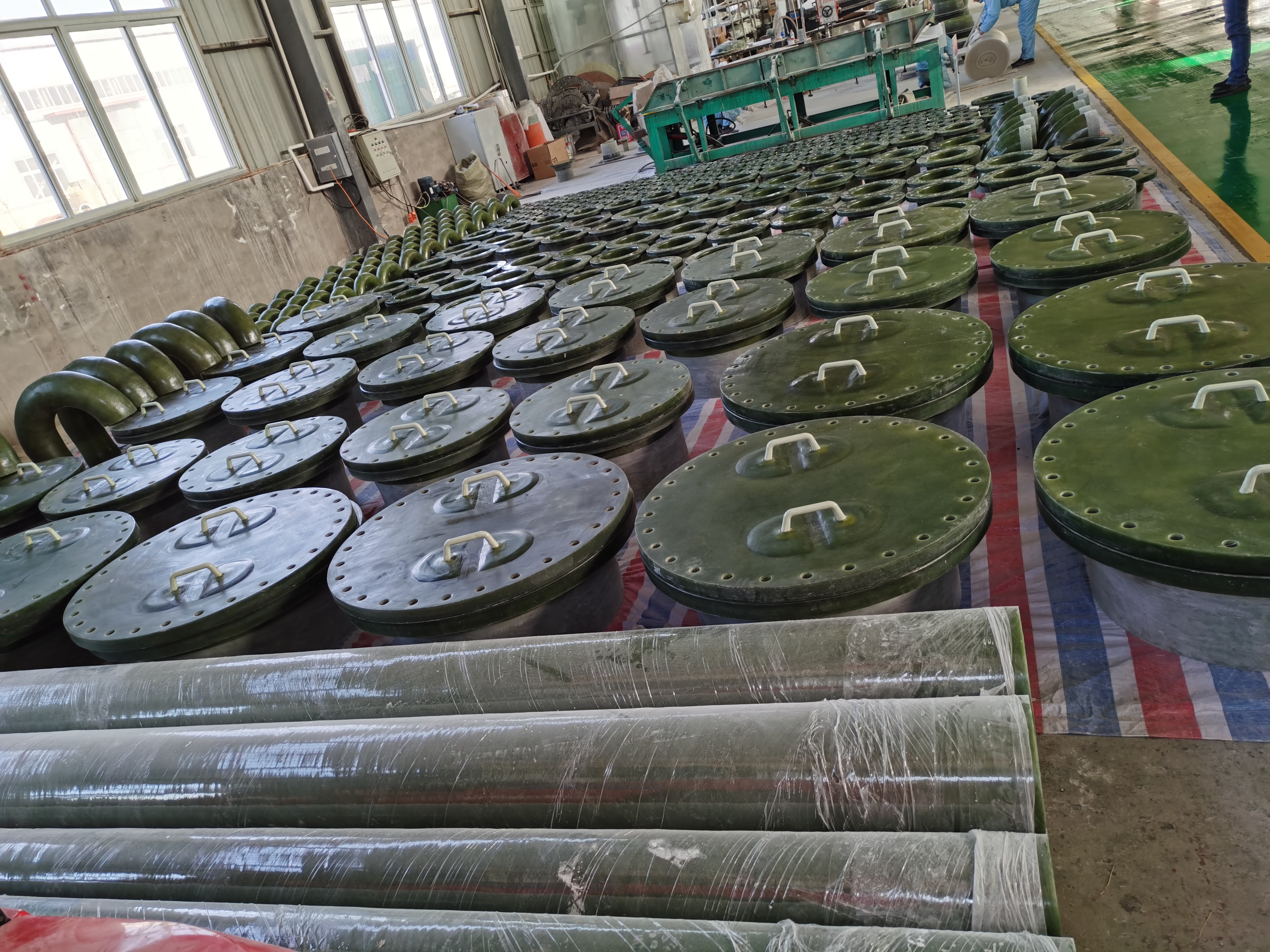

Durable PVC and FRP Tanks for Efficient Liquid Storage Solutions

Understanding PVC and FRP Tanks Applications, Benefits, and Considerations

In various industries, storage tanks play a pivotal role in the safe and efficient handling of liquids and materials. Among the myriad options available, PVC (polyvinyl chloride) and FRP (fiber-reinforced plastic) tanks have garnered attention for their unique properties and applications. In this article, we explore the characteristics, benefits, and common uses of PVC and FRP tanks, shedding light on why they are gaining popularity in both industrial and commercial sectors.

The Basics of PVC and FRP Tanks

PVC is a widely-used synthetic plastic polymer that is known for its durability, corrosion resistance, and lightweight nature. It is particularly effective in environments where chemical handling is essential, making it an ideal material for storage and transport of various liquids.

On the other hand, FRP is a composite material made by combining a polymer matrix (which can include epoxy, polyester, or vinyl ester) with a reinforcing agent such as fiberglass. This combination results in a strong, lightweight product that is also resistant to corrosion, UV degradation, and extreme temperatures.

Both PVC and FRP tanks offer excellent performance in storing a variety of substances, from water to industrial chemicals. Their construction allows them to maintain structural integrity under stress, making them a reliable choice for numerous applications.

Advantages of PVC and FRP Tanks

1. Corrosion Resistance One of the most significant benefits of PVC and FRP tanks is their inherent resistance to corrosive substances. Unlike metal tanks, which can rust or degrade when exposed to harsh chemicals, PVC and FRP provide a longer lifespan, reducing the need for frequent replacements and maintenance.

2. Cost-Effectiveness Both PVC and FRP tanks are typically less expensive than their metal counterparts, leading to lower upfront costs. Their durability also means that in the long run, businesses can save money on repairs and replacements.

pvc frp tank

3. Lightweight Both types of tanks are significantly lighter than traditional storage tanks made from glass or metal, making them easier to transport and install. This feature is particularly valuable in situations where weight restrictions are a concern.

4. Versatility PVC and FRP tanks can be custom-designed to meet specific needs, including size and shape. This flexibility makes them suitable for various applications, from water storage for agricultural use to chemical containment in industrial settings.

5. Low Maintenance Due to their durable construction and corrosion resistance, PVC and FRP tanks require minimal maintenance over time. This factor allows operators to focus on other critical areas of their operations without the constant concern of tank deterioration.

Applications of PVC and FRP Tanks

PVC and FRP tanks are widely used across various sectors due to their adaptability. Some common applications include

- Water Treatment Facilities These tanks are used for storing and treating water, ensuring a reliable supply for industrial processes, municipalities, and agriculture. - Chemical Storage Many industries that handle aggressive chemicals prefer PVC and FRP tanks for storing acids, alkalis, and other hazardous materials. - Waste Management The durable composition of these tanks makes them ideal for holding waste products, including industrial waste and biosolids.

- Food and Beverage Industries Specific grades of FDA-approved PVC and FRP tanks are utilized for storing food, beverages, and other consumables, ensuring safety and compliance with health standards.

Conclusion

In summary, PVC and FRP tanks are versatile storage solutions that offer significant advantages in terms of durability, cost-effectiveness, and maintenance. Their ability to withstand corrosive materials while remaining lightweight and easy to install makes them appealing for various industries. As businesses seek efficient and reliable solutions for their storage needs, the importance of PVC and FRP tanks is likely to continue growing, cementing their place in the market as trusted options for liquid storage. Exploring the specific requirements of your application can help determine the most suitable type of tank, ensuring optimal performance and longevity in your operations.