-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

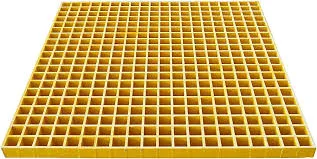

rectangular tank made of fiberglass material

The Benefits of Using Fiberglass for Rectangular Tanks

In the world of industrial storage solutions, the choice of materials plays a crucial role in determining the efficiency, longevity, and safety of the structures involved. Among the various materials available, fiberglass has emerged as a preferred choice for constructing rectangular tanks. This article explores the numerous advantages of fiberglass tanks, highlighting their structural integrity, cost-effectiveness, and environmental impact.

Structural Integrity and Durability

Fiberglass, known for its remarkable strength-to-weight ratio, offers superior structural integrity compared to traditional materials such as steel or concrete. Rectangular tanks made of fiberglass are designed to withstand various external pressures and environmental conditions. The composite material is resistant to corrosion, which is a significant advantage when storing chemicals or other hazardous substances. Unlike metal tanks that may rust over time or concrete tanks that can crack, fiberglass tanks maintain their structural integrity, reducing the need for frequent repairs or replacements.

Moreover, the lightweight nature of fiberglass allows for easier installation and transportation. Traditional materials often require heavy machinery and extensive labor for setup, while fiberglass tanks can be easily maneuvered and installed with minimal workforce, thereby lowering labor costs and project timelines.

Cost-Effectiveness

One of the compelling reasons for using fiberglass in tank construction is its cost-effectiveness. Although fiberglass tanks can have a higher upfront cost when compared to alternatives like plastic or metal, their long-term savings make them a wise investment. The longevity of fiberglass significantly reduces replacement costs. Additionally, their low maintenance requirements contribute to savings over time, as operators do not need to allocate extensive budgets for upkeep.

Energy efficiency in production and installation also plays a role in the overall cost savings. Fiberglass manufacturing processes have evolved, allowing for reduced energy consumption compared to traditional materials. Moreover, the lightweight nature of fiberglass means that transportation costs are significantly lower than those associated with heavier materials.

rectangular tank made of fiberglass material

Environmental Impact

With growing concerns over environmental protection and sustainability, choosing the right materials has never been more critical. Fiberglass is increasingly recognized for its environmental advantages. The production of fiberglass tanks often involves less energy and fewer harmful emissions compared to metals or concrete, making them a more sustainable choice. Additionally, fiberglass can be recycled, and advancements in technology continue to improve recycling methods, further minimizing the environmental footprint.

The impact on the ecosystem is another vital consideration. Fiberglass tanks can be designed to be sealed and leak-proof, preventing contaminants from escaping into the surrounding environment. This aspect is particularly crucial in industries where hazardous materials are stored, ensuring compliance with environmental regulations and protecting local ecosystems.

Versatility and Customization

Fiberglass rectangular tanks are incredibly versatile and can be customized to meet various specifications and requirements. Industries ranging from agriculture to wastewater treatment can benefit from tailored solutions, making fiberglass an ideal choice for various applications. Whether it’s for storing water, chemicals, or food products, fiberglass tanks can be designed to meet the storage requirements precisely.

Customization extends beyond size and shape; fiberglass can also be engineered to provide specific thermal or chemical resistance properties. This flexibility ensures these tanks can perform reliably across a broad spectrum of industries and conditions.

Conclusion

In summary, the use of fiberglass for constructing rectangular tanks presents a multitude of benefits. With their exceptional structural integrity, reduced maintenance costs, and positive environmental footprint, fiberglass tanks are an ideal choice for a wide range of applications. As industries continue to prioritize sustainable and cost-effective solutions, fiberglass is likely to play an increasingly significant role in the future of storage solutions. Embracing such advancements not only enhances operational efficiency but also contributes to a more sustainable approach to industrial practices. Thus, it is clear that fiberglass is more than just a material; it is a stepping stone towards innovative and responsible storage solutions.