-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 11, 2025 18:20

Back to list

rectangular tank with dimensions for grp calculation.

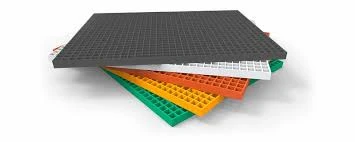

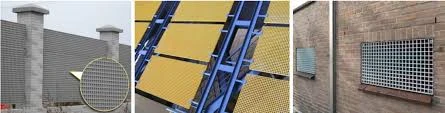

Rectangular tanks, especially those designed with composite materials like Glass Reinforced Plastic (GRP), are increasingly popular in industries such as chemical processing, water treatment, and aquaculture. Their appeal is due, in part, to GRP’s blend of durability, corrosion resistance, and cost-effectiveness. For businesses planning to utilize these tanks, it’s critical to understand the factors influencing their design, particularly dimensions, and how these impact GRP calculations.

The thickness of the GRP layer is a critical parameter. It must be sufficient to withstand both internal pressure from the stored liquid and external forces. Engineers often use finite element analysis (FEA) to simulate stress distributions and optimize the GRP layer thickness specific to the tank's size and application conditions. Reinforcement Needs Customizing for Strength Moreover, structural reinforcements might be necessary depending on tank size and operational stressors (e.g., temperature variations, mechanical impacts). Stiffeners and ribs are common reinforcement additions in larger tanks to enhance load-bearing capacity and minimize deformation under stress. Trust in Expertise Selecting the Right Supplier Selecting a reputable supplier with expertise in GRP tank manufacturing is crucial. An authoritative supplier not only provides high-quality materials but also contributes valuable insights into the optimal tank design for specific applications. The supplier's credibility and track record instill trust that the tank will perform reliably over its lifespan. Installation and Maintenance Sustaining Quality Proper installation and routine maintenance are necessary to sustain a GRP tank’s functionality and extend its lifespan. Understanding the environmental conditions and operational parameters helps in scheduling timely inspections and repairs, ensuring the tank remains in prime condition. Real-world Application Gaining Experience In practice, the use of GRP rectangular tanks has been transformative across various industries. Companies have leveraged these tanks to streamline processes, reduce costs on repairs and replacements, and enhance safety through improved material attributes. Success stories and testimonials from industry peers further demonstrate the efficacy of using rectangular GRP tanks tailored to precise dimensional and material specifications. In conclusion, understanding the interplay between a rectangular tank’s dimensions and its GRP requirements is essential for optimizing its design and function. Through precise calculations and expert guidance, businesses can ensure these tanks meet their specific needs, delivering performance and reliability consistent with industry expectations. Employing this knowledge holistic approach elevates a company’s operational efficiency and product integrity, underscoring the importance of expertise and trustworthiness in industrial design and engineering choices.

The thickness of the GRP layer is a critical parameter. It must be sufficient to withstand both internal pressure from the stored liquid and external forces. Engineers often use finite element analysis (FEA) to simulate stress distributions and optimize the GRP layer thickness specific to the tank's size and application conditions. Reinforcement Needs Customizing for Strength Moreover, structural reinforcements might be necessary depending on tank size and operational stressors (e.g., temperature variations, mechanical impacts). Stiffeners and ribs are common reinforcement additions in larger tanks to enhance load-bearing capacity and minimize deformation under stress. Trust in Expertise Selecting the Right Supplier Selecting a reputable supplier with expertise in GRP tank manufacturing is crucial. An authoritative supplier not only provides high-quality materials but also contributes valuable insights into the optimal tank design for specific applications. The supplier's credibility and track record instill trust that the tank will perform reliably over its lifespan. Installation and Maintenance Sustaining Quality Proper installation and routine maintenance are necessary to sustain a GRP tank’s functionality and extend its lifespan. Understanding the environmental conditions and operational parameters helps in scheduling timely inspections and repairs, ensuring the tank remains in prime condition. Real-world Application Gaining Experience In practice, the use of GRP rectangular tanks has been transformative across various industries. Companies have leveraged these tanks to streamline processes, reduce costs on repairs and replacements, and enhance safety through improved material attributes. Success stories and testimonials from industry peers further demonstrate the efficacy of using rectangular GRP tanks tailored to precise dimensional and material specifications. In conclusion, understanding the interplay between a rectangular tank’s dimensions and its GRP requirements is essential for optimizing its design and function. Through precise calculations and expert guidance, businesses can ensure these tanks meet their specific needs, delivering performance and reliability consistent with industry expectations. Employing this knowledge holistic approach elevates a company’s operational efficiency and product integrity, underscoring the importance of expertise and trustworthiness in industrial design and engineering choices.

Related Products