-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

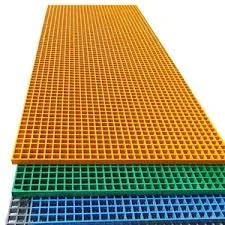

Durable Solutions with Reinforced Plastic Pipes for Enhanced Infrastructure Performance

Reinforced Plastic Pipe The Future of Piping Solutions

When it comes to modern infrastructure, the choice of materials plays a pivotal role in ensuring durability, efficiency, and cost-effectiveness. Among various materials used in piping systems, reinforced plastic pipes have gained considerable attention due to their superior properties, versatility, and growing applications in various industries. This article delves into the features, benefits, and applications of reinforced plastic pipes, highlighting their importance in contemporary engineering and construction.

What are Reinforced Plastic Pipes?

Reinforced plastic pipes (RPP) are composite materials made by combining a plastic matrix—usually polyvinyl chloride (PVC), polyethylene (PE), or polypropylene (PP)—with reinforcing materials such as fiberglass or carbon fibers. This combination enhances the mechanical properties of the plastic, resulting in pipes that exhibit improved strength, rigidity, and resistance to environmental factors. The reinforcing materials also provide additional benefits, such as increased temperature resistance and reduced weight, making RPP an excellent alternative to traditional materials like metal or concrete.

Key Benefits of Reinforced Plastic Pipes

1. Corrosion Resistance One of the standout features of reinforced plastic pipes is their resistance to corrosion. Unlike metal pipes that are susceptible to rust and degradation from various chemicals, RPPs maintain structural integrity even when exposed to harsh conditions. This makes them ideal for applications in chemical processing plants, wastewater treatment facilities, and other corrosive environments.

2. Lightweight and Easy to Handle Compared to traditional piping materials, reinforced plastic pipes are significantly lighter. This characteristic simplifies transportation and installation, reducing labor costs and construction time. The ease of handling also minimizes the risk of injury during installation.

3. Durability and Longevity With their enhanced strength and resistance to wear, reinforced plastic pipes can last for decades without needing significant maintenance or replacement. This durability translates to lower life-cycle costs, making RPPs a wise investment for infrastructure projects.

4. Temperature and Pressure Resistance The reinforcement offered by fiberglass or carbon fibers allows these pipes to withstand higher pressure and temperature variations than conventional plastic pipes. This capability makes RPPs suitable for hot water applications and high-pressure systems.

reinforced plastic pipe

5. Environmental Impact Reinforced plastic pipes are often manufactured using recyclable materials, contributing to sustainability efforts in various industries. Their longevity reduces the frequency of replacements, further minimizing environmental impact over time.

Applications of Reinforced Plastic Pipes

Given their numerous advantages, reinforced plastic pipes have found applications across a broad spectrum of industries

- Water and Wastewater Management RPPs are commonly used in municipal water supply systems and sewage treatment plants due to their corrosion resistance and durability. - Industrial Applications Many manufacturing processes involve corrosive substances, making RPPs ideal for transporting chemicals safely. Their lightweight nature further contributes to their utility in industrial settings.

- Oil and Gas In the exploration and transportation of oil and gas, reinforced plastic pipes are increasingly preferred due to their strength and resistance to chemical erosion.

- Construction Reinforced plastic pipes are used in plumbing, drainage, and irrigation systems, providing a robust solution for building projects.

- Electrical Conduits The non-conductive nature of reinforced plastic makes it a suitable option for electrical conduits, ensuring safety and reliability.

Conclusion

As industries continue to seek innovative solutions that meet the demands of modern infrastructure, reinforced plastic pipes emerge as a superior alternative to conventional materials. With their numerous advantages—including corrosion resistance, lightweight design, and increased longevity—RPPs are transforming the landscape of piping installations across various sectors. As technology advances and the need for sustainable building practices grows, it is clear that reinforced plastic pipes will play a significant role in shaping the future of piping solutions.