-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

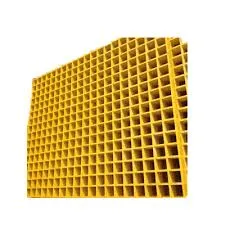

reinforced plastic pipe

The Advantages and Applications of Reinforced Plastic Pipes

Reinforced plastic pipes (RPP) have revolutionized the piping industry by offering a lightweight, durable, and cost-effective solution for various applications. Made from a combination of polymers and reinforcing materials—typically fiberglass or other composites—RPP has become increasingly popular in industries such as construction, agriculture, chemical processing, and water management. In this article, we will explore the advantages and applications of reinforced plastic pipes and why they are becoming a go-to choice for many engineers and designers.

Advantages of Reinforced Plastic Pipes

1. Durability One of the primary advantages of reinforced plastic pipes is their incredible durability. These pipes are resistant to a wide range of chemicals, making them suitable for transporting corrosive substances. Additionally, their ability to withstand extreme temperatures—ranging from sub-zero conditions to high heat—ensures that they can perform well in various environments.

2. Lightweight Compared to traditional materials such as steel or concrete, reinforced plastic pipes are significantly lighter. This attribute simplifies handling and installation, reducing labor costs and time on-site. Contractors appreciate the ease of transportation and the minimal need for heavy equipment during installation.

3. Flexibility and Adaptability RPP can be manufactured in various diameters and wall thicknesses, allowing for tremendous flexibility in design. This adaptability makes it easier to customize solutions for specific projects, whether for municipal water systems or complex industrial applications. The resistance to impact and bending is another benefit, as it allows the pipes to accommodate changes in the environment without breaking.

4. Cost-effective Although the initial cost may be similar to traditional piping materials, the long-term benefits of RPP can lead to significant savings. Their resistance to corrosion and reduced maintenance needs mean lower lifecycle costs. Moreover, the fast installation times associated with RPP often translate to lower project costs overall.

5. Eco-friendly Many reinforced plastic pipes are manufactured with sustainability in mind. They can be produced with recycled materials, and their longevity means that they do not need to be replaced as often as conventional materials, reducing waste. Additionally, their lightweight nature helps lower the carbon footprint associated with transportation.

reinforced plastic pipe

Applications of Reinforced Plastic Pipes

1. Water Supply Systems RPP is widely used in municipal water systems, where resistance to corrosion and chemical leaching is crucial. The pipes are ideal for transporting potable water and can also handle wastewater effectively.

2. Agriculture In agriculture, reinforced plastic pipes serve as irrigation systems and drainage pipes. Their ability to withstand environmental stressors while remaining lightweight makes them an excellent choice for modern agricultural practices that rely on efficient water management.

3. Chemical Applications The chemical industry frequently utilizes RPP for pipelines that transport dangerous substances. Their resistance to corrosion and chemical damage ensures safety and reliability in processes involving hazardous materials.

4. Telecommunications RPP is increasingly being utilized in telecommunications infrastructure. The lightweight nature of the pipes allows for easy installation of fiber optic cables, while their durability ensures minimal signal loss and protection from environmental factors.

5. Construction In construction, RPP is used for various applications, including underground utilities, stormwater management, and even as part of structural components in various building designs. The flexibility of RPP allows it to be integrated into complex structures with varying requirements.

Conclusion

Reinforced plastic pipes represent a significant advancement in piping technology, merging high performance with versatility. Their many advantages—ranging from durability and lightweight construction to long-term cost efficiency—make them an excellent choice for a wide range of applications across different industries. As the demand for sustainable and reliable infrastructure grows, RPP is likely to play a critical role in the future of piping solutions. Whether in municipal water systems, agricultural initiatives, or industrial processes, the adoption of reinforced plastic pipes is a trend worth watching.