-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 16, 2025 03:26

Back to list

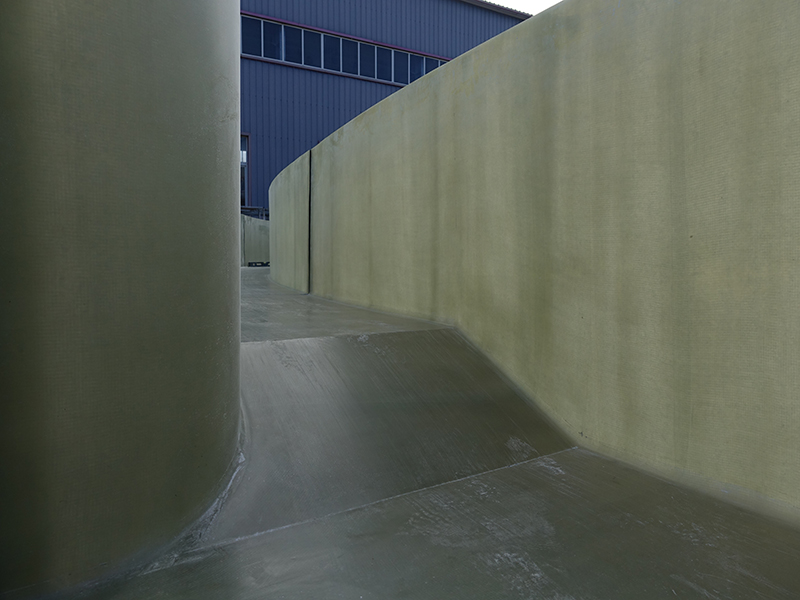

reinforced plastic pipe

Reinforced plastic pipes (RPPs) are indeed revolutionizing the industry with their impressive characteristics and versatile applications. As experts delve deeper into the materials and technology behind these pipes, they continue to unveil advantages that cement their importance in various sectors, particularly construction and infrastructure.

Due to these pronounced benefits, stakeholders are increasingly trusting RPPs in major infrastructure projects. Trustworthiness stems from both the theoretical groundwork defining their design and the empirical evidence illustrating their performance. Rigorous testing under field and laboratory conditions continues to verify the extraordinary service life and cost-effectiveness of RPP systems. As users gain trust in the material, they witness substantial reductions in operational hazards, insurance liabilities, and overall lifecycle costs. The intertwined scientific expertise and authoritative industry endorsement behind reinforced plastic pipes reinforce their status as a groundbreaking product. Infrastructure leaders are embracing these advantages, aligning practical needs with advanced, trustworthy technology. Moreover, improved resource management through RPP utilization promises a more sustainable future, minimizing ecological impacts and promoting responsible production processes. In conclusion, reinforced plastic pipes resonate with qualities that exemplify their role as industrial game-changers. Practitioners relying on their effectiveness benefit from reduced costs and downtime, while scientific trials and user confidence bolster their market penetrance. Expertly engineered, reinforced plastic pipes offer an unmatched balance of durability, flexibility, and sustainability — paving the way for future advancements in the industry. With these pipes, the journey toward resilient and reliable infrastructure solutions continues to gain momentum, underscoring the essential role of innovation in shaping tomorrow’s industrial landscape.

Due to these pronounced benefits, stakeholders are increasingly trusting RPPs in major infrastructure projects. Trustworthiness stems from both the theoretical groundwork defining their design and the empirical evidence illustrating their performance. Rigorous testing under field and laboratory conditions continues to verify the extraordinary service life and cost-effectiveness of RPP systems. As users gain trust in the material, they witness substantial reductions in operational hazards, insurance liabilities, and overall lifecycle costs. The intertwined scientific expertise and authoritative industry endorsement behind reinforced plastic pipes reinforce their status as a groundbreaking product. Infrastructure leaders are embracing these advantages, aligning practical needs with advanced, trustworthy technology. Moreover, improved resource management through RPP utilization promises a more sustainable future, minimizing ecological impacts and promoting responsible production processes. In conclusion, reinforced plastic pipes resonate with qualities that exemplify their role as industrial game-changers. Practitioners relying on their effectiveness benefit from reduced costs and downtime, while scientific trials and user confidence bolster their market penetrance. Expertly engineered, reinforced plastic pipes offer an unmatched balance of durability, flexibility, and sustainability — paving the way for future advancements in the industry. With these pipes, the journey toward resilient and reliable infrastructure solutions continues to gain momentum, underscoring the essential role of innovation in shaping tomorrow’s industrial landscape.

Related Products