-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality Rock Drill Rods for Mining and Construction Applications

Rock Drill Rod for MF Bits Essential for Mining and Construction

In the realm of mining and construction, efficiency and durability are paramount. One of the critical components that enhance drilling performance is the rock drill rod, specifically designed for MF (Medium Frequency) bits. These rods are not just simple tools; they are intricate engineering solutions that play a vital role in various applications, such as mineral extraction, foundation drilling, and tunnel construction.

Understanding Rock Drill Rods

A rock drill rod serves as the connector between the drilling machine and the drill bit. Made from high-quality steel, these rods are designed to withstand the harsh conditions often encountered in mining and construction environments. Their primary function is to transmit both rotational energy and impact force to the drill bit, enabling it to penetrate tough rock formations effectively.

Features of MF Bits

MF bits are designed for medium-frequency applications, making them versatile for different geological conditions. They are engineered to optimize drilling efficiency and reduce wear and tear. When paired with rock drill rods, these bits can achieve remarkable penetration rates, improving overall productivity on job sites. The combination ensures that the energy from the drill is effectively delivered to the bit, allowing for faster and more efficient drilling.

Importance of Material Selection

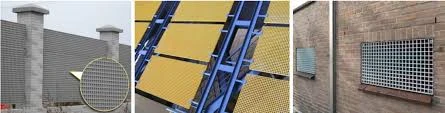

rock drill rod for mf bits, suitable for mining and construction ...

The manufacturing process of rock drill rods involves careful material selection. High tensile strength steel is commonly used due to its ability to resist fatigue and wear. Furthermore, heat treatment processes enhance their toughness and tensile strength, making them suitable for heavy-duty applications. The durability of these rods significantly reduces the frequency of replacements, leading to cost savings and minimized downtime.

Suitable Applications in Mining and Construction

Rock drill rods and MF bits find applications in various sectors. In mining, they are used for drilling boreholes for exploitation of mineral resources. Their ability to drill deep into hard rock formations makes them invaluable for mineral extraction processes. In construction, these tools are essential for creating foundations, drilling wells, and carrying out geotechnical investigations. The versatility of MF bits allows them to penetrate a variety of materials, including granite, basalt, and limestone, making them effective in diverse environments.

Enhancing Operational Efficiency

Using high-quality rock drill rods with MF bits can lead to significant improvements in operational efficiency. Efficient drilling not only speeds up project timelines but also ensures safety on job sites. Poorly designed or inferior quality rods can lead to equipment failure or accidents, which can severely impact both productivity and safety. Therefore, investing in reliable equipment is crucial for any mining or construction project.

In conclusion, rock drill rods designed for MF bits are critical tools in the mining and construction industries. Their robust construction, compatibility with medium-frequency bits, and ability to deliver operational efficiency make them indispensable. As technology advances, further enhancements in the design and materials used for these tools are expected, promising even greater efficiency and safety in future drilling operations. For any contractor or mining operation seeking to optimize their drilling processes, choosing the right rock drill rod is a fundamental step towards achieving success.