-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

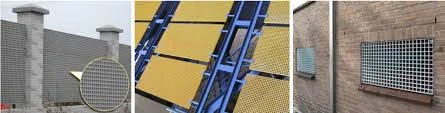

rock drill rod for mf bits, suitable for mining and construction

Rock Drill Rods for MF Bits Essential Tools for Mining and Construction

In the vigorous environments of mining and construction, efficiency and reliability are paramount. Among the myriad tools employed in these sectors, rock drill rods designed for multi-function (MF) bits play a crucial role. These rods not only enhance the drilling process but also ensure that operations proceed smoothly and safely. This article explores the importance, features, and advantages of using rock drill rods with MF bits for various applications in mining and construction.

What Are Rock Drill Rods?

Rock drill rods are cylindrical tools used to transmit rotational and axial forces from drilling rigs to the drill bit. They are an integral component of the drilling assembly, contributing to the penetration and efficiency of the drilling process. MF bits, or multi-function bits, are specifically engineered to handle various drilling conditions and rock formations, making them highly versatile.

Importance in Mining and Construction

In mining, the need for precision and speed is critical. Drill rods must withstand harsh conditions, including extreme temperatures and rugged terrain. Using rock drill rods with MF bits allows operators to perform a range of functions, from drilling blast holes to performing exploratory drilling, all with minimal downtime.

In construction, the versatility of MF bits can accommodate different tasks, such as concrete drilling and geological exploration, which are often required in urban development. The efficiency of these rods means projects can proceed on schedule, meeting tight deadlines and maintaining cost-effectiveness.

Key Features of Rock Drill Rods for MF Bits

1. Durability Made from high-strength steel or alloy materials, these rods are designed to resist wear and tear, ensuring longevity in even the most challenging environments.

rock drill rod for mf bits, suitable for mining and construction

3. Performance Many modern rock drill rods feature advanced manufacturing techniques that optimize performance, including superior thread designs that enhance the connection strength and stability during drilling operations.

4. Lightweight Design New materials and manufacturing processes have led to the creation of lighter rods, which not only reduce operator fatigue but also allow for easier transportation and handling.

Advantages of Using Rock Drill Rods with MF Bits

1. Versatility One of the significant advantages of MF bits is their ability to adapt to various drilling conditions. Rock drill rods that accommodate these bits make it easier to switch between different applications, leading to increased productivity on site.

2. Increased Efficiency With better energy transfer due to improved design and material strength, drilling can occur at a faster rate, which is crucial in time-sensitive projects.

3. Reduced Maintenance The durability of modern rock drill rods minimizes the frequency of replacements and repairs, further enhancing efficiency and reducing operational costs.

Conclusion

Rock drill rods designed for MF bits are indispensable tools in the mining and construction industries. Their durability, versatility, and efficiency contribute significantly to the overall productivity of a project. As technology continues to evolve, these rods are likely to become even more advanced, offering new solutions for the challenges faced in drilling operations. By investing in high-quality rock drill rods and multi-function bits, companies can ensure that they are equipped to handle the demands of today’s dynamic work environments.