-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

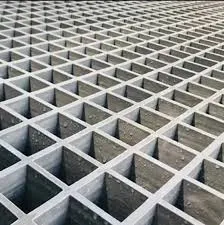

rock drill rod for mf bits, suitable for mining and construction ...

Understanding Rock Drill Rods for Mining and Construction Enhancements in MF Bits

In the dynamic and challenging world of mining and construction, the role of rock drill rods cannot be overstated. These essential tools contribute significantly to the efficiency and effectiveness of drilling operations, especially in conjunction with MF (Middle Frequency) bits. This article delves into the intricacies of rock drill rods tailored for MF bits, exploring their advantages, applications, and the technology driving their improvements.

What Are Rock Drill Rods?

Rock drill rods are long, cylindrical rods that connect drilling machines to drill bits. Their primary function is to transfer the rotational force generated by the drilling machine to the drill bit, enabling efficient penetration into various rock formations. Rock drill rods come in various sizes, lengths, and materials, depending on specific applications in mining and construction.

The Importance of MF Bits

MF bits are designed to operate effectively in medium-frequency drilling applications. They have features that allow them to balance between speed and torque, providing a versatile solution for different drilling conditions—whether in softer or harder rock formations. Their design optimizes fragmentation, ensuring that rocks are broken into manageable sizes that can be efficiently removed from the drill site.

Compatibility between Rock Drill Rods and MF Bits

To optimize drilling performance, compatibility between rock drill rods and MF bits is vital. This compatibility affects not just the drilling efficiency but also the durability of both components. High-quality rock drill rods are engineered from robust materials, such as high tensile steel, which provide the necessary strength to withstand the stresses encountered during drilling. Furthermore, these rods are often treated with advanced surface coatings to enhance their wear resistance and longevity.

Another crucial factor is the threading system that connects the rods and bits. Precision-engineered threads ensure a secure fit that minimizes the risk of failure during operation. The right configuration enhances torque transmission while also facilitating easy connection and disconnection when changing bits in the field.

Benefits of Advanced Rock Drill Rod Technology

rock drill rod for mf bits, suitable for mining and construction ...

1. Increased Durability Advances in material science have led to the development of high-grade alloys and heat treatments that dramatically improve the lifespan of rock drill rods. This results in fewer replacements and reduced operational downtime.

2. Enhanced Performance Innovations in design, such as tapered or fluted configurations, allow rock drill rods to reduce drag and improve the flow of drilling fluids. This results in efficient debris removal from the borehole, ensuring uninterrupted drilling operations.

3. Cost Efficiency While the initial investment in high-quality rock drill rods may be higher, their durability and performance often lead to reduced overall drilling costs. Fewer maintenance needs and lower failure rates translate to savings over the long term.

4. Versatility Modern rock drill rods are adaptable for diverse drilling applications. Their compatibility with various MF bits allows them to operate effectively across different geological conditions, making them valuable for both mining and construction sectors.

Applying Rock Drill Rods in Mining and Construction

In mining, rock drill rods equipped with MF bits are indispensable for tasks such as exploration drilling, production drilling, and as part of specialized processes like blast hole drilling. The ability to penetrate hard rock while maintaining speed and torque makes them ideal for unearthing minerals, coal, and other underground resources.

In construction, rock drill rods facilitate the creation of foundational structures, tunnels, and other infrastructures. Their efficiency in drilling larger diameters in shorter time frames can lead to accelerated project timelines, meeting the demands of modern construction schedules.

Conclusion

As mining and construction industries continue to evolve, the technology surrounding rock drill rods and MF bits is set to advance further. The integration of improved materials, innovative designs, and enhanced compatibility will undoubtedly lead to more efficient drilling operations. By understanding the critical role of rock drill rods in conjunction with MF bits, industry professionals can better appreciate the tools that drive their success and ensure safer, more effective drilling practices. As we look to the future, investing in high-quality equipment like rock drill rods will remain a priority for anyone dedicated to excelling in these demanding fields.