-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

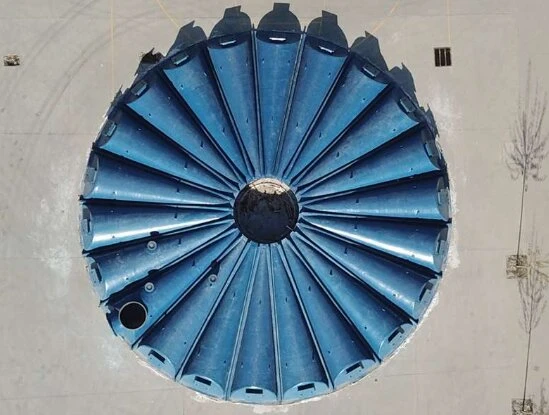

rock drill rod for mf bits, suitable for mining and construction

Rock Drill Rods for MF Bits Essential Tools for Mining and Construction

In the world of mining and construction, efficiency and durability are paramount. Among the essential tools that contribute to successful operations are rock drill rods, particularly those designed for MF (Multipurpose) bits. These rods play a crucial role in optimizing drilling processes while withstanding the harsh conditions often encountered in such environments.

Understanding Rock Drill Rods

Rock drill rods are long, cylindrical tools used to connect the drill bit to the drill rig. They are designed to transmit torque and impact energy from the rig to the drill bit. The design and material composition of these rods are vital, as they must endure extreme pressure, high temperatures, and abrasive materials encountered during drilling operations.

MF Bits are a specific type of drill bit that excels in various applications, including mining, quarrying, and construction. They are characterized by their versatility and efficiency, making them a popular choice in the industry. When paired with high-quality rock drill rods, MF bits can significantly enhance drilling productivity and effectiveness.

Materials and Construction

The performance of rock drill rods largely depends on the materials used in their construction. Most rods are made from high-strength steel, which provides the necessary toughness and resistance to wear. Additionally, some advanced rods can incorporate materials like alloy steels and special coatings, which can enhance their durability and longevity.

The manufacturing process of rock drill rods involves precision engineering and rigorous quality control measures. These processes ensure that the rods meet the specific requirements for strength, flexibility, and resistance to bending or breaking under severe conditions. The result is a reliable product that workers can trust in demanding environments.

rock drill rod for mf bits, suitable for mining and construction

Applications in Mining and Construction

In mining, rock drill rods equipped with MF bits are used to create boreholes for resource extraction, such as coal, copper, and precious metals. Their ability to penetrate hard rock formations efficiently makes them indispensable in the mining sector. The adaptability of MF bits allows for drilling in various geological conditions, contributing to increased production rates and reduced downtime.

In construction, these drill rods facilitate the installation of foundations, anchor bolts, and other essential components of structures. The need for precision and reliability in construction cannot be overstated, as even minor errors can lead to significant complications. Rock drill rods designed for MF bits ensure that holes are drilled accurately and efficiently, paving the way for safer and more robust structures.

Benefits of Using High-Quality Rock Drill Rods

Investing in high-quality rock drill rods offers numerous advantages. Firstly, they provide increased drilling efficiency, reducing time and labor costs. Secondly, the durability ensures fewer replacements and maintenance stops, leading to overall lower operational costs. Lastly, the reliability of these tools enhances worker safety by minimizing the risk of equipment failure during operations.

Furthermore, manufacturers often provide valuable support and technical advice, ensuring that operators select the right tools for their specific applications. This knowledge transfer contributes to more successful and productive drilling campaigns.

Conclusion

In summary, rock drill rods for MF bits are vital components in the mining and construction industries. Their robust construction, efficient performance, and adaptability to various conditions make them indispensable tools. As technology advances, we can expect further innovations in drill rod manufacturing, enhancing their capabilities and contributing to the growth of these crucial sectors. Investing in high-quality rock drill rods ultimately leads to improved operational efficiency, cost-effectiveness, and safety on the job site.