-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

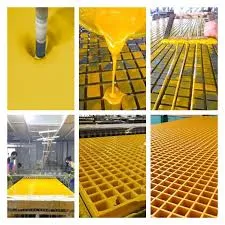

rtrp pipe

Understanding RTRP The Future of Efficient Pipeline Systems

In the world of industrial operations, the efficiency and reliability of pipeline systems are paramount. One of the leading concepts in this arena is the RTRP (Reinforced Thermosetting Resin Pipe) system, which has gained significant attention for its innovative approach to fluid transport. By blending the durability of traditional materials with advanced technologies, RTRP systems offer substantial advantages across various sectors, including oil and gas, water management, and chemical transportation.

What is RTRP?

RTRP, or Reinforced Thermosetting Resin Pipe, is a type of composite pipe that combines a thermosetting resin with reinforcing materials like fiberglass or other composites. This structure results in a lightweight yet extremely durable product that stands up to high-pressure environments and corrosive substances, making it an ideal choice for industries that require robust and sustainable solutions.

One of the defining features of RTRP is its ability to withstand harsh environmental conditions. Unlike traditional pipes made from metals or plastics, RTRP is resistant to UV radiation, chemical exposures, and temperature fluctuations, allowing it to maintain integrity and performance over extended periods.

Applications of RTRP

The versatility of RTRP pipes has led to a broad range of applications. In the oil and gas sector, RTRP systems are revolutionizing the way hydrocarbon products are transported. These pipes can handle the demands of high-pressure operations while minimizing the risk of leaks and spills, thereby enhancing safety and environmental protection.

In water management, RTRP is proving invaluable for infrastructure projects. Its resistance to corrosion and scale formation ensures a longer service life compared to conventional pipes, reducing the frequency and costs associated with maintenance and replacement. Furthermore, the lightweight nature of RTRP simplifies installation, allowing for quicker project completion and reduced labor costs.

Understanding RTRP The Future of Efficient Pipeline Systems

Benefits of RTRP

rtrp pipe

The advantages of RTRP extend beyond just its durability. The following are some key benefits

1. Cost-Effectiveness While the initial investment may be higher compared to traditional piping systems, the long-term savings generated through reduced maintenance, longevity, and efficiency often outweigh those costs.

2. Lightweight Nature RTRP’s reduced weight not only simplifies transportation and handling but also minimizes the structural requirements for support systems, leading to further cost savings.

3. Ease of Installation The installation process for RTRP systems is usually faster and less labor-intensive, enabling quicker project timelines and the ability to meet urgent operational demands.

4. Environmental Resistance The ability to resist a wide range of environmental factors translates into prolonged service life and fewer disruptions due to system failure, which is critical in maintaining consistent operations across industries.

5. Versatility RTRP pipes can be customized for various applications, allowing companies to tailor solutions to specific operational needs without compromising performance.

Conclusion

As industries worldwide continue to prioritize efficiency, safety, and sustainability, RTRP represents a significant advancement in pipeline technology. Its unique combination of strength, light weight, and resistance to environmental challenges positions it as a front-runner in the quest for innovative fluid transport solutions.

With ongoing research and development, the applications for RTRP are expected to expand even further, paving the way for smarter, more effective, and environmentally friendly pipeline systems in the future. As we look ahead, embracing technologies like RTRP will be essential for industries aiming to thrive in an increasingly competitive and eco-conscious landscape.