-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

'shank adapter producer'

The Role of Shank Adapter Producers in Modern Manufacturing

In the rapidly evolving world of manufacturing, the demand for precision and efficiency has never been higher. At the heart of this transformation lies a critical component the shank adapter. Producers of shank adapters play an essential role in various industries, including automotive, aerospace, and construction, providing the necessary tools that ensure machinery runs smoothly and efficiently.

The Role of Shank Adapter Producers in Modern Manufacturing

The process of producing shank adapters involves advanced engineering and precision manufacturing techniques. Producers often utilize Computer Numerical Control (CNC) machining, which allows for exceptional accuracy and consistency. CNC machines can create complex geometries with tight tolerances that are essential for the proper fitting and functioning of shank adapters. Additionally, manufacturers may employ materials such as high-speed steel, carbide, or even specialized alloys to ensure durability and performance under extreme conditions.

'shank adapter producer'

Quality assurance is another critical aspect of shank adapter production. Producers must adhere to stringent industry standards and regulations to ensure their products meet the necessary safety and performance benchmarks. This often involves rigorous testing procedures to assess factors such as tensile strength, wear resistance, and overall ergonomic design. A robust quality control process is vital, as failures in these components can lead to significant operational disruptions and safety hazards in manufacturing settings.

Moreover, the role of shank adapter producers extends beyond manufacturing. They often engage in research and development (R&D) to innovate and enhance their products. With the rise of automation and smart manufacturing technologies, producers are now exploring how to integrate sensors and IoT capabilities into shank adapters. These advancements can provide real-time data on tool performance and wear, allowing manufacturers to preemptively address issues before they lead to downtime.

Sustainability has also become a focal point for shank adapter producers. As industries worldwide strive for greener practices, many manufacturers are looking for ways to reduce waste and improve energy efficiency in their processes. This may involve sourcing sustainable materials, minimizing scrap during production, or creating longer-lasting products that require less frequent replacement.

In conclusion, the role of shank adapter producers is pivotal in driving efficiency, safety, and innovation within modern manufacturing. By providing reliable and high-quality adapters, these producers contribute significantly to the overall productivity and effectiveness of various industries. As technology continues to advance, the importance of these components will only grow, making shank adapter producers key players in the future of manufacturing. The continuous development in materials, design, and smart technologies will ensure that they remain at the forefront of this ever-evolving field.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

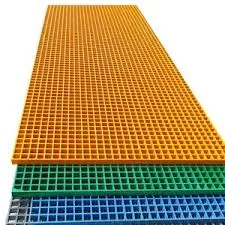

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025