-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

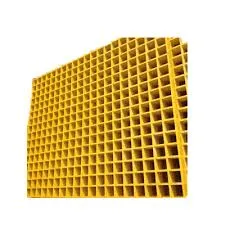

Lightweight Vehicle Designed from FRP Materials for Enhanced Performance and Efficiency

The Future of Lightweight Vehicles Exploring FRP Car Technology

In the rapidly evolving automotive industry, the quest for lightweight materials has become paramount. As manufacturers strive to improve fuel efficiency and reduce emissions, Fiber Reinforced Plastics (FRP) have emerged as a game-changer. These innovative materials offer the strength of traditional metals while significantly reducing weight. This article explores the advantages and potential of FRP in the production of lightweight vehicles and what this means for the future of automotive design.

What is FRP?

Fiber Reinforced Plastics (FRP) are composite materials made by combining a polymer matrix with fibrous materials, such as glass or carbon fibers. The resulting composite boasts remarkable properties it is lightweight, strong, and resistant to corrosion. These attributes make FRP an ideal candidate for vehicle manufacturing, where reducing weight can enhance performance and efficiency.

Advantages of Using FRP in Vehicle Production

1. Weight Reduction The most significant advantage of FRP is its lightweight nature. Vehicles made from FRP can be up to 30% lighter than those constructed with traditional materials like steel or aluminum. This reduction in weight translates to better fuel economy and reduced greenhouse gas emissions, crucial factors amid global climate concerns.

2. Fuel Efficiency The integration of FRP into vehicle design has profound implications for fuel efficiency. Lighter vehicles require less energy to move, which directly reduces fuel consumption. With rising fuel prices and increasing environmental regulations, consumers and manufacturers are prioritizing vehicles that maximize efficiency.

3. Design Flexibility FRP materials can be molded into intricate shapes that would be difficult or impossible to achieve with metal. This design flexibility allows for more aerodynamic vehicle shapes, which can further enhance efficiency and performance. Manufacturers can also customize designs to meet specific aesthetic demands without compromising on functionality.

similar titles for frp car lightweight vehicle made of ...

4. Durability and Longevity FRP is resistant to corrosion, making it a suitable choice for vehicles that operate in harsh environments. Unlike metal, which can rust and degrade over time, FRP maintains its integrity, leading to lower maintenance costs and extended vehicle life. This durability is particularly beneficial in regions with extreme weather conditions.

5. Sustainability As the automotive industry faces increasing scrutiny regarding sustainability, FRP offers a more environmentally friendly option. Many FRP materials can be recycled, contributing to a circular economy. Furthermore, the reduced weight of vehicles can lead to lower overall carbon emissions, aligning with global sustainability goals.

Challenges and Considerations

Despite its many advantages, the use of FRP in vehicle production is not without challenges. One major obstacle is the cost of production. Currently, FRP can be more expensive to manufacture than traditional materials, which can deter some manufacturers from making the switch. Additionally, the recycling processes for FRP are still in development, which could limit its sustainability in the short term.

Another consideration is the technology required for the effective integration of FRP into existing manufacturing processes. Manufacturers may need to invest in new equipment and training for workers, further complicating the shift to FRP.

The Road Ahead

As technology progresses, it is likely that the challenges associated with using FRP in car manufacturing will be addressed. Collaborations between material scientists, automotive engineers, and manufacturers will pave the way for more economical and efficient production processes.

The future of automotive design is undoubtedly shifting towards lightweight structures, with FRP leading the charge. As consumers become more environmentally conscious and demand vehicles that balance performance with sustainability, the automotive industry is poised for significant transformations. In conclusion, the potential of FRP in creating lightweight vehicles is immense, offering a glimpse into a future where cars are not only lighter and more efficient but also more aligned with the principles of sustainability and innovation.