-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

similar titles for frp car lightweight vehicle made of ...

The Future of Automotive Engineering FRP Lightweight Vehicles

In recent years, the automotive industry has undergone a seismic shift towards sustainability and efficiency, prompting manufacturers to explore innovative materials that can significantly enhance vehicle performance. Among these materials, Fiberglass Reinforced Plastics (FRP) have emerged as a leading solution for producing lightweight vehicles. Through understanding the advantages and potential applications of FRP, we can envisage a future where cars are not only lighter and faster but also more environmentally friendly.

The Benefits of FRP in Vehicle Manufacturing

FRP is a composite material consisting of a polymer matrix reinforced with fibers, typically glass. This combination provides a unique blend of strength and lightweight characteristics. One of the most notable benefits of using FRP in automotive manufacturing is the significant weight reduction it offers compared to traditional materials like steel and aluminum. A lighter vehicle translates to improved fuel efficiency and reduced carbon emissions, which are critical factors in addressing climate change.

Moreover, FRP possesses excellent resistance to corrosion and fatigue, which enhances the durability and longevity of vehicles. Unlike metal components that may rust over time, FRP maintains its structural integrity under various environmental conditions. This durability reduces maintenance costs and extends the vehicle's lifespan, making it a wise investment for manufacturers and consumers alike.

Enhanced Design Flexibility

Another compelling advantage of FRP is its design flexibility. It can be molded into complex shapes more easily than traditional materials, allowing for greater creativity and innovation in vehicle design. This capability not only enables manufacturers to create aerodynamic forms that improve performance but also facilitates the integration of advanced technological features. As the automotive market increasingly leans towards electric and hybrid models, the lightweight property of FRP becomes even more advantageous in maximizing battery efficiency.

Safety Considerations

similar titles for frp car lightweight vehicle made of ...

While the lightweight nature of FRP is a distinct advantage, safety remains a paramount concern in vehicle design. Interestingly, FRP can be engineered to provide significant impact resistance, safeguarding passengers during collisions. Many industries, including aerospace and marine, have long relied on FRP for its protective qualities, and its application in automobiles promises similar advances in safety technology.

Sustainability and Environmental Impact

In addition to performance enhancements, the use of FRP aligns with the automotive industry's push towards sustainability. The production process of FRP can be tailored to reduce waste and energy consumption, further decreasing the carbon footprint associated with vehicle manufacturing. Additionally, as recycling technologies for composite materials continue to evolve, the environmental benefits of FRP are likely to increase, positioning it as a responsible choice for the future of automotive production.

Challenges and Future Directions

Despite its numerous advantages, the widespread adoption of FRP in automotive manufacturing is not without challenges. The initial costs of production can be higher than traditional materials, mainly due to the specialized processes required to mold and cure FRP components. However, as technology advances and economies of scale are realized, these costs are expected to decrease, making FRP a more accessible option for manufacturers.

Furthermore, ongoing research into the recyclability of FRP will be crucial in addressing concerns regarding the environmental impact of disposed materials. Developing effective recycling methods could pave the way for a circular economy in the automotive sector, where materials are continuously reused and repurposed.

Conclusion

In summary, FRP presents a promising avenue for the future of automotive engineering. Its lightweight properties, combined with durability, design flexibility, and environmental benefits, position it as a formidable alternative to traditional materials. As the industry continues to innovate and address existing challenges, we are likely to witness a new era in vehicle manufacturing, where cars are not only more efficient and sustainable but also embody the cutting edge of design and technology. The evolution of FRP lightweight vehicles represents a crucial step toward a greener, smarter automotive future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

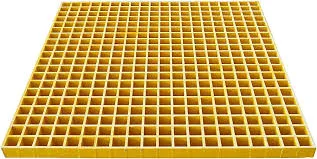

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025