-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Lightweight FRP Vehicles for Enhanced Performance and Fuel Efficiency in Modern Automotive Design

The Future of Lightweight Vehicles Exploring FRP Technology

In the dynamic landscape of automotive engineering, the pursuit of weight reduction has become a paramount objective. As manufacturers strive to enhance fuel efficiency, performance, and environmental sustainability, the integration of advanced materials like Fiberglass Reinforced Plastics (FRP) is revolutionizing the design and production of lightweight vehicles. This article delves into the significance of FRP in creating high-performance cars, along with its benefits and challenges.

The Rise of Lightweight Vehicles

With increasing environmental concerns and rising fuel prices, there is a growing demand for lightweight vehicles that offer superior efficiency without compromising safety and performance. The automotive industry recognizes that every kilogram shed from a vehicle's weight can lead to substantial improvements in fuel economy and reduced emissions. Consequently, manufacturers are turning to materials that provide an excellent strength-to-weight ratio, and FRP stands out as a leading contender.

What is FRP?

Fiberglass Reinforced Plastics are composite materials made from a polymer matrix reinforced with fiberglass. This combination results in a durable and lightweight material that can withstand significant stress while being resistant to corrosion and environmental degradation. FRP offers the benefit of shape versatility, allowing engineers to design complex geometries that traditional metals cannot achieve.

Advantages of FRP in Automotive Applications

1. Weight Reduction One of the most significant advantages of FRP is its lightweight nature. Vehicles made with FRP components can weigh significantly less than those constructed from traditional materials like steel and aluminum. This reduction not only improves fuel efficiency but also enhances acceleration, braking, and overall handling.

2. Corrosion Resistance Unlike metals, FRP is inherently resistant to rust and corrosion, which extends the lifespan of vehicle components and reduces maintenance costs. This durability is particularly beneficial in harsh environments or regions with extreme weather conditions.

3. Design Flexibility FRP allows for greater design freedom, enabling manufacturers to create streamlined, aerodynamic shapes that improve vehicle performance. Complex designs can be produced efficiently, leading to enhanced aesthetic appeal and brand differentiation.

similar titles for frp car lightweight vehicle made of ...

4. Thermal Properties FRP has excellent thermal insulation properties, reducing heat transfer within the vehicle. This can lead to improved comfort levels for passengers and reduced energy consumption for climate control systems.

5. Sustainability As the automotive industry pivots toward sustainable practices, the use of FRP aligns with these initiatives. Many FRP products can be recycled and repurposed, minimizing environmental impact.

Challenges of Using FRP

While the advantages of FRP are clear, there are challenges that manufacturers must consider

1. Cost The initial cost of FRP materials and processing can be higher than traditional materials. However, as technology advances and production techniques improve, this gap is gradually narrowing.

2. Manufacturing Complexity The production of FRP components often requires specialized skills and equipment. This can lead to longer production times compared to more conventional approaches.

3. Performance Limitations While FRP is strong, it may not always match the mechanical properties of high-strength metals in high-stress applications, such as shock absorption in crash scenarios. Ongoing research aims to address these limitations and enhance FRP's performance in critical areas.

Conclusion

The integration of Fiberglass Reinforced Plastics in the automotive industry represents a significant leap toward the development of lightweight vehicles. As manufacturers continue to innovate and optimize these materials, the future of automotive design will likely feature an increasing reliance on FRP, paving the way for vehicles that are not only lighter and more efficient but also more sustainable. The journey towards a greener and more efficient automotive landscape is only just beginning, and FRP is set to play a pivotal role in this transformation. As we advance into this new era, the synergy between engineering ingenuity and material science will undoubtedly shape the evolution of transportation.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

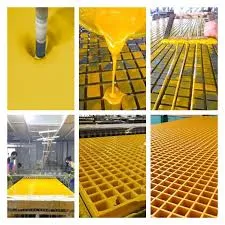

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025