-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

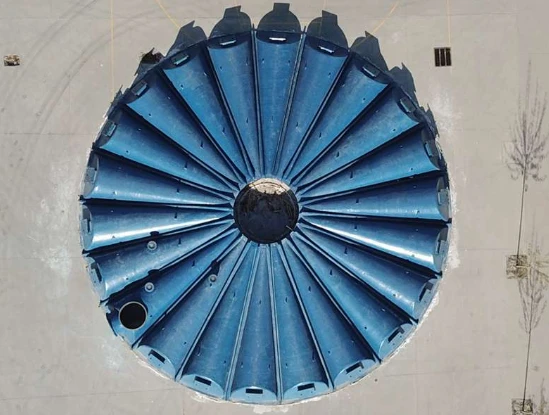

Lightweight FRP Vehicle Design Innovations for Enhanced Performance and Efficiency

Exploring the Benefits of FRP in Lightweight Vehicle Design

In the quest for fuel efficiency, performance, and reduced emissions, the automotive industry has witnessed a significant shift towards lightweight vehicle design. One of the key materials that have emerged in this transformation is Fiber Reinforced Polymer (FRP). This innovative composite material is composed of a polymer matrix reinforced with fibers (such as glass, carbon, or aramid), providing an excellent strength-to-weight ratio that is crucial in vehicle manufacturing. This article delves into the advantages of using FRP in lightweight vehicle design and its potential for the future of the automotive industry.

Weight Reduction and Fuel Efficiency

One of the primary reasons for incorporating FRP in vehicle design is its incredible lightweight properties. Vehicles manufactured with FRP components can weigh significantly less than those made with traditional materials like steel or aluminum. For instance, studies indicate that switching to FRP can result in weight savings of up to 30-50%. This reduction in weight directly correlates to improved fuel efficiency and lower emissions. Lighter vehicles require less energy to accelerate, which translates into better mileage and reduced environmental impact.

Enhanced Strength and Durability

While being lightweight, FRP materials do not compromise on strength. In fact, composites can offer superior strength and rigidity compared to metal counterparts. This robustness ensures that vehicles constructed with FRP can withstand considerable stress and impacts, potentially enhancing safety for passengers. Additionally, FRP has excellent resistance to corrosion and environmental degradation, meaning that components made from this material can have a longer lifespan, reducing the need for frequent repairs or replacements.

Design Flexibility

FRP offers designers and engineers remarkable flexibility in creating complex shapes and structures that would be difficult or impossible to achieve with metals. This adaptability allows for innovative vehicle designs that enhance both aerodynamic efficiency and aesthetic appeal. Furthermore, the ability to mold FRP into intricate forms can lead to improvements in vehicle performance by optimizing airflow and reducing drag, thus contributing further to fuel efficiency.

similar titles for frp car lightweight vehicle made of ...

Cost-Effectiveness

While initial costs for FRP manufacturing can be higher than traditional materials, the long-term economic benefits often outweigh these concerns. The reduction in weight leads to lower fuel costs over the vehicle's life cycle. Moreover, the durability of FRP materials minimizes maintenance and repair expenses. As manufacturers scale up production and technology advances, the costs associated with FRP are expected to decrease, making it a more viable option for widespread adoption in the automotive sector.

Sustainability Benefits

As the automotive industry moves towards more sustainable practices, FRP provides an attractive solution. Many FRP composites can be designed to be recyclable, meaning that at the end of a vehicle's lifecycle, materials can be repurposed rather than ending up in landfills. Additionally, the fuel efficiency gained through lightweight design contributes to a reduction in greenhouse gas emissions, aligning with global targets for sustainability.

Future Implications for the Automotive Industry

The ongoing research and development within the field of FRP technology are paving the way for even more advanced applications in lightweight vehicle design. Innovations such as self-healing composites and smart materials that respond to environmental conditions are on the horizon, promising to further enhance vehicle performance and safety. As companies continue to invest in FRP technology, we can expect to see a broader acceptance of these materials in mass-produced vehicles.

Conclusion

In conclusion, Fiber Reinforced Polymer is revolutionizing the design and manufacturing of lightweight vehicles, offering a compelling mix of benefits that include weight reduction, enhanced strength, design flexibility, cost-effectiveness, and sustainability. As the automotive industry increasingly prioritizes efficiency and environmental consciousness, the adoption of FRP is likely to become more widespread. The future of vehicle design is undoubtedly leaning toward innovative materials like FRP, which will not only redefine performance standards but also contribute significantly to a greener planet. As we navigate this exciting possibility, the automotive landscape will undoubtedly change, leading to a new era of lightweight and eco-friendly vehicles.