-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 11, 2025 21:09

Back to list

similar titles for frp car lightweight vehicle made of ...

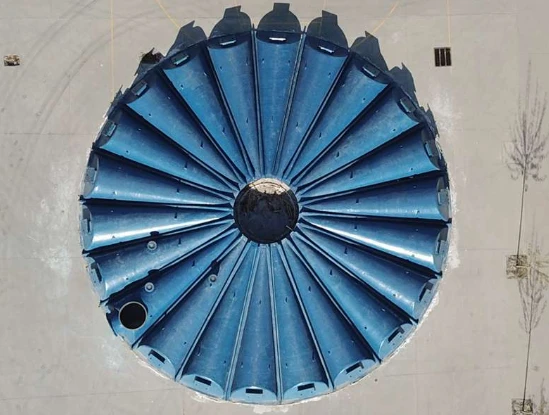

Fiber Reinforced Plastic (FRP) has revolutionized the automotive industry, specifically in the design and manufacture of lightweight vehicles. As the demand for fuel efficiency and sustainable solutions intensifies, engineers and manufacturers are increasingly looking towards FRP for its blend of durability, cost-effectiveness, and design flexibility. This material is not only redefining what is possible but breaking new grounds in automotive innovation.

Moreover, cars made from FRP demonstrate remarkable durability and longevity. The corrosion-resistant property of FRP ensures a longer lifespan for vehicles, particularly in regions with harsh weather conditions. Steel parts, for instance, can succumb to rust and corrosion over time, necessitating frequent replacements. FRP components, on the other hand, resist these environmental stressors, ensuring that vehicles maintain their integrity and safety longer. In terms of expertise, creating vehicles with FRP requires proficiency in advanced material sciences and engineering techniques. Engineers must understand the complex behaviors of composite materials to maximize their potential. This includes knowledge of anisotropic mechanical properties, curing processes, and the ability to predict performance under various stresses. Manufacturers investing in FRP technology are often at the forefront of innovation, spearheading new methods and paradigms in vehicle production. Addressing the question of authoritativeness, leading car manufacturers are validating the use of FRP in production models. By integrating FRP into critical vehicle components, such as chassis, body panels, and interior parts, these companies are showcasing the material's capabilities in real-world applications. Their documented success stories and rigorous testing establish a precedent that solidifies FRP's reliability and efficacy. Trustworthiness, from a consumer's perspective, hinges on the proven track records that validate FRP's benefits. Real-world testing and performance data provide insight into FRP's durability and efficiency, reinforcing consumer confidence. Moreover, as credentials play a crucial role, associations with experienced manufacturers and industry leaders further bolster trust. In conclusion, the development of lightweight vehicles made from FRP represents a confluence of advanced material technology and visionary design philosophy. FRP not only contributes to creating more efficient vehicles but aligns with the broader goals of sustainability and innovation. As the automotive sector evolves, embracing FRP could well be the stepping stone to a future where performance, sustainability, and efficiency exist in perfect harmony.

Moreover, cars made from FRP demonstrate remarkable durability and longevity. The corrosion-resistant property of FRP ensures a longer lifespan for vehicles, particularly in regions with harsh weather conditions. Steel parts, for instance, can succumb to rust and corrosion over time, necessitating frequent replacements. FRP components, on the other hand, resist these environmental stressors, ensuring that vehicles maintain their integrity and safety longer. In terms of expertise, creating vehicles with FRP requires proficiency in advanced material sciences and engineering techniques. Engineers must understand the complex behaviors of composite materials to maximize their potential. This includes knowledge of anisotropic mechanical properties, curing processes, and the ability to predict performance under various stresses. Manufacturers investing in FRP technology are often at the forefront of innovation, spearheading new methods and paradigms in vehicle production. Addressing the question of authoritativeness, leading car manufacturers are validating the use of FRP in production models. By integrating FRP into critical vehicle components, such as chassis, body panels, and interior parts, these companies are showcasing the material's capabilities in real-world applications. Their documented success stories and rigorous testing establish a precedent that solidifies FRP's reliability and efficacy. Trustworthiness, from a consumer's perspective, hinges on the proven track records that validate FRP's benefits. Real-world testing and performance data provide insight into FRP's durability and efficiency, reinforcing consumer confidence. Moreover, as credentials play a crucial role, associations with experienced manufacturers and industry leaders further bolster trust. In conclusion, the development of lightweight vehicles made from FRP represents a confluence of advanced material technology and visionary design philosophy. FRP not only contributes to creating more efficient vehicles but aligns with the broader goals of sustainability and innovation. As the automotive sector evolves, embracing FRP could well be the stepping stone to a future where performance, sustainability, and efficiency exist in perfect harmony.

Related Products