-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Toothed Button Bit for Enhanced Precision in Cutting Applications

Exploring the Innovative Design of Toothed Button Bits in Mining Applications

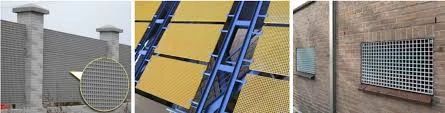

The mining industry relies heavily on advanced technology and specialized tools to extract resources efficiently and safely. Among these innovations, the toothed button bit has emerged as a key component in drilling operations, particularly for hard rock formations. This article aims to delve into the design, functionality, and advantages of toothed button bits, shedding light on why they are being adopted widely in modern mining applications.

Understanding Toothed Button Bits

Toothed button bits, as the name suggests, are cutting tools with protruding teeth that protrude from their surfaces, designed to break rock during the drilling process. Unlike traditional flat bits, which primarily rely on weight and rotation to penetrate the rock, toothed bits take a more aggressive approach. The teeth are engineered to create fractures in hard materials, allowing for more effective penetration and faster drilling speeds.

These bits come in various sizes and designs, making them versatile for different applications. The shape and arrangement of the teeth can be customized to suit specific types of rock formations, making toothed button bits an essential tool in the toolkit of mining engineers.

The Design and Engineering Behind Toothed Button Bits

The design of a toothed button bit is a fine balance between functionality and durability. Typically made from high-strength steel alloys, these bits are capable of withstanding the extreme pressures and forces encountered during drilling. The teeth themselves are usually made from tungsten carbide, a material known for its hardness and wear resistance.

The engineering behind the placement and shape of the teeth is crucial. Each tooth's angle and projection are designed to maximize rock fragmentation while minimizing bit wear. This meticulous design approach not only enhances the efficiency of drilling operations but also prolongs the lifespan of the bit, resulting in reduced operational costs.

similar title to button tooth bit could be toothed button bit for

Advantages of Toothed Button Bits

1. Improved Penetration Rates One of the most significant advantages of toothed button bits is their ability to achieve higher penetration rates compared to traditional bits. The aggressive cutting action generated by the teeth allows for faster drilling, which is essential in large-scale mining operations where time and efficiency are critical.

2. Versatility in Applications Toothed button bits can be used in various geological conditions. Whether drilling through hard granite or softer sedimentary rock, these bits can be tailored to meet the challenges of different environments. This versatility reduces the need for multiple types of bits, simplifying inventory and logistics.

3. Reduced Bit Wear The robust design and high-quality materials used in toothed button bits result in less wear and tear over time. This durability translates to fewer bit replacements and less downtime during drilling operations, thereby enhancing productivity.

4. Cost-Effectiveness While the initial investment in high-quality toothed button bits may be higher than traditional options, the long-term savings associated with efficiency and durability often justify the cost. Mining companies can save money on operational expenses by reducing the frequency of bit changes and minimizing drill time.

Future of Toothed Button Bits

As the mining industry continues to evolve, so too will the technology behind toothed button bits. Innovations in material science and engineering are likely to lead to even more advanced designs, further optimizing drilling performance. Additionally, the integration of AI and data analytics may provide insights into the ideal configurations for specific drilling scenarios, paving the way for smarter, more efficient mining operations.

In conclusion, toothed button bits are revolutionizing the mining industry with their efficient design, application versatility, and cost-effectiveness. As mining engineers seek to improve productivity in an environmentally conscious manner, the role of such advanced cutting tools will become increasingly significant. By understanding the advantages and potential of toothed button bits, companies can better equip themselves to meet the challenges of modern mining and capitalize on the opportunities ahead.