-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Designs in Strongwell Grating for Enhanced Durability and Safety Applications

Understanding Strongwell Grating The Perfect Solution for Industrial Applications

Strongwell grating, a prominent product in the realm of industrial construction and design, offers robust solutions for various applications, particularly in environments that demand strength, safety, and corrosion resistance. Constructed primarily from fiberglass reinforced plastic (FRP), Strongwell grating presents a compelling alternative to traditional metal gratings, making it increasingly popular in sectors such as chemical processing, water treatment, pulp and paper industries, and marine environments.

Composition and Properties

At its core, Strongwell grating is fabricated using a combination of resins and fiberglass. This composition not only imparts exceptional strength and stability but also makes the grating remarkably lightweight. The use of fiberglass means that the material is inherently resistant to rust and corrosion, which are common issues associated with metals, especially in harsh or wet environments. Moreover, the grating can be manufactured with fire-retardant properties, adding an extra layer of safety where fire hazards may be present.

Variety and Versatility

One of the standout features of Strongwell grating is its versatility. It comes in a variety of styles, including molded and pultruded options, allowing for a wide range of applications. Molded grating is created by combining resin and fiberglass in a mold, resulting in a product that offers excellent slip resistance due to its textured surface. Conversely, pultruded grating is produced by continuously pulling raw materials through a heated die, making it incredibly strong and well-suited for heavy loads.

In terms of size, Strongwell gratings can be fabricated in various dimensions to fit specific project requirements, ensuring customization for unique applications. This adaptability is crucial for industries that often require tailored solutions to optimize efficiency and safety.

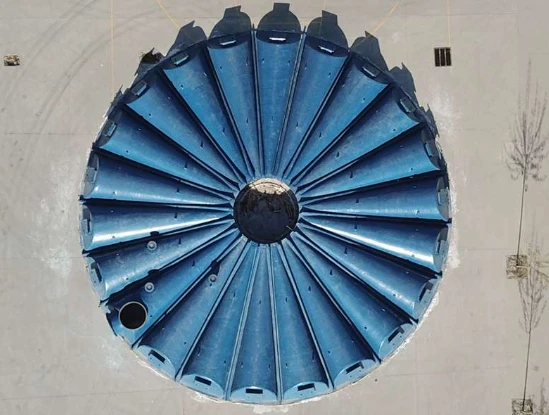

strongwell grating

Applications Across Industries

Strongwell grating is particularly advantageous in environments subjected to corrosive elements. In the chemical industry, for instance, it is widely used for flooring, walkways, and stair treads. Its corrosion-resistant properties ensure a longer lifespan compared to traditional metal options, which can suffer from rapid degradation in such settings. Water treatment facilities also benefit from its use, where it plays a significant role in offering safe walkways and platforms that remain resilient against damp and potentially corrosive conditions.

Furthermore, the marine industry utilizes Strongwell grating for docks, marinas, and other waterfront structures. Its anti-slip surface provides safety for individuals working or navigating these areas, reducing the risk of accidents caused by wet surfaces. Additionally, the lightweight nature of the material makes it easier and more cost-effective to transport and install, further enhancing its appeal.

Sustainability Factor

As environmental concerns grow in prominence, Strongwell grating presents a sustainable option. Its long lifespan reduces the need for frequent replacement, thus minimizing waste. Moreover, fiberglass is a material that can be recycled, providing an opportunity to mitigate environmental impact. Manufacturers are also increasingly focusing on sustainable practices in the production of these materials, ensuring that they adhere to eco-friendly standards.

Conclusion

In summary, Strongwell grating stands out as a top-tier solution for modern industrial applications. With its exceptional properties such as corrosion resistance, lightweight nature, and versatility, it meets the diverse needs of various sectors while ensuring safety and durability. As industries continue to evolve and encounter new challenges, the adoption of innovative materials like Strongwell grating is likely to increase, paving the way for safer, more efficient, and sustainable solutions. Whether it’s for flooring, walkways, or marine applications, Strongwell grating has proven itself as a reliable choice for demanding environments.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025