-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

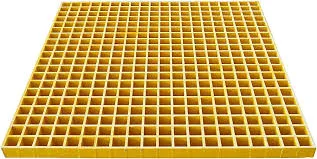

strongwell grating

Exploring Strongwell Grating Innovations in Industrial Solutions

In the realm of industrial applications, the demand for durable and effective materials continues to rise. One of the standout solutions that have emerged in recent years is Strongwell grating. Known for its remarkable strength-to-weight ratio and versatility, Strongwell grating is revolutionizing various industries, including construction, wastewater management, and marine applications.

What is Strongwell Grating?

Strongwell grating is a type of fiberglass reinforced plastic (FRP) grating designed to provide an efficient and cost-effective solution for flooring and walkways. It is manufactured through a process that combines sturdy fiberglass with resin, resulting in a composite material that offers exceptional durability, corrosion resistance, and lightweight properties. Unlike traditional steel grating, Strongwell grating does not rust, making it an ideal choice for environments where moisture and chemical exposure are prevalent.

Key Benefits of Strongwell Grating

1. Corrosion Resistance One of the most significant advantages of Strongwell grating is its resistance to a wide range of corrosive environments. This feature is particularly beneficial in industries like chemical processing and wastewater treatment, where exposure to harsh chemicals is common.

2. Lightweight but Strong Strongwell grating’s lightweight design simplifies installation and reduces the overall load on supporting structures. Despite its light weight, it maintains structural integrity, making it suitable for heavy-duty applications.

3. Safety Features Safety is a paramount concern in industrial settings. Strongwell grating provides excellent slip resistance, which helps in preventing accidents in wet or oily conditions. Moreover, its open design allows for drainage, significantly reducing the risk of standing water.

strongwell grating

4. Customizability Another notable benefit of Strongwell grating is its versatility. It can be custom-fabricated to meet specific project requirements, including varying thicknesses, mesh sizes, colors, and finishes. This adaptability makes it suitable for a wide array of applications, from pedestrian walkways to vehicular access.

5. Cost-Effective While the initial investment may be higher than traditional materials, Strongwell grating offers long-term savings. Its durability and low maintenance requirements mean that it does not need frequent replacements or repairs, ultimately leading to cost savings over time.

Applications of Strongwell Grating

The applications of Strongwell grating are vast and diverse. In the construction and infrastructure sector, it is commonly used in walkways, platforms, and steps due to its lightweight properties and ease of installation. The marine industry also benefits from Strongwell grating's corrosion resistance, making it a preferred option for docks, piers, and offshore platforms.

In wastewater treatment facilities, Strongwell grating is employed for trench covers, platforms, and access walkways. Its ability to withstand chemical exposure ensures longevity in these challenging environments. Additionally, Strongwell grating finds applications in food processing plants, where hygiene and cleanliness are paramount.

Conclusion

As industries continue to evolve and adopt new technologies, materials like Strongwell grating are at the forefront of innovation. With its unique combination of strength, durability, and safety, it addresses many of the challenges faced in harsh industrial environments. As stakeholders seek sustainable and long-term solutions, the use of Strongwell grating exemplifies how advanced materials can enhance operational efficiency while ensuring safety and reliability.

In summary, Strongwell grating is more than just a functional material; it is a solution that can transform the way industries operate. As businesses look to enhance their infrastructure while minimizing risk and maintenance costs, Strongwell grating stands out as a sophisticated choice that aligns with modern industrial needs.