-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

t38 drill rod analysis

Analyzing T38 Drill Rod Performance Insights and Innovations

The mining and drilling industry is continuously evolving, with advancements in technology and materials playing a critical role in enhancing operational efficiency. Among the various components used in drilling operations, the T38 drill rod has gained significant attention due to its unique characteristics and performance in challenging environments. This article aims to analyze the T38 drill rod, highlighting its advantages, applications, and the latest innovations that are shaping its future.

The T38 drill rod, specifically designed for percussion drilling, is part of a series of rods characterized by their tapering structure and robust build. One of the primary features of the T38 rod is its diameter, which typically measures 38mm, making it ideal for both small- to medium-sized operations where versatility and efficiency are paramount. Its design allows for a high penetration rate and efficient energy transfer, making it suitable for a range of geological conditions, from soft to hard rock.

Advantages of T38 Drill Rods

1. Durability and Strength One of the standout characteristics of the T38 drill rod is its exceptional durability. Made from high-quality steel and treated for strength, the rod can withstand high levels of stress and strain, ensuring a longer operational life.

2. Weight and Handling The T38 rod strikes a balance between weight and strength. Its manageable weight enhances handling and transportation, reducing operator fatigue and increasing safety during installation and removal.

3. Efficiency in Drilling The T38 drill rod is designed for optimum energy transfer during the drilling process. This efficiency leads to quicker drilling times and lower fuel consumption, which is essential for reducing operational costs in the long run.

t38 drill rod analysis

4. Versatile Applications The versatility of the T38 drill rod enables its use in various applications, including geotechnical drilling, mineral exploration, and geothermal drilling. Its adaptability makes it a favorite among contractors and drilling companies looking for a reliable solution across multiple projects.

Innovations Influencing T38 Drill Rods

In recent years, the drilling industry has witnessed substantial innovations that have further enhanced the performance of T38 drill rods. One such advancement is the implementation of advanced alloy compositions that increase strength while reducing weight. These materials not only improve the durability of the rods but also provide better resistance to wear and corrosion.

Additionally, manufacturers are now utilizing advanced coating technologies to enhance the surface properties of T38 drill rods. These coatings can improve resistance to wear, prolonging the lifespan of the rod and reducing the frequency of replacements, which is crucial for maintaining productivity.

Furthermore, the integration of smart technology and real-time monitoring systems into drilling operations adds another layer of efficacy. By equipping T38 drill rods with sensors, operators can track performance metrics, analyze drilling efficiency, and make data-driven decisions. This technological advancement not only optimizes drilling operations but also helps in anticipating maintenance needs, minimizing downtime.

Conclusion

The T38 drill rod remains an essential tool in the drilling industry, offering a blend of strength, efficiency, and versatility. With ongoing innovations in materials and technology, its performance continues to improve, ensuring that it meets the demands of modern drilling operations. As the industry moves forward, the T38 drill rod is poised to play a pivotal role in enhancing productivity and sustainability in drilling practices, making it a vital component for mining and exploration companies worldwide. Through continued research and development, the T38 drill rod will evolve to meet future challenges, affirming its position as a cornerstone in the drilling landscape.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

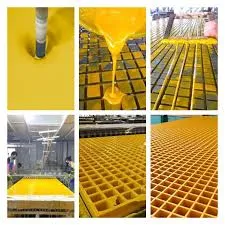

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025