-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

tapered drill string a closer look at its design and applications

A Closer Look at Tapered Drill String Design and Applications

The oil and gas industry has witnessed significant advancements in drilling technologies over the years, and one of the remarkable innovations is the tapered drill string. This sophisticated drilling technology plays a crucial role in improving efficiency, reducing costs, and enhancing the overall performance of drilling operations. In this article, we will explore the design of tapered drill strings and discuss their various applications in today’s drilling endeavors.

Understanding Tapered Drill Strings

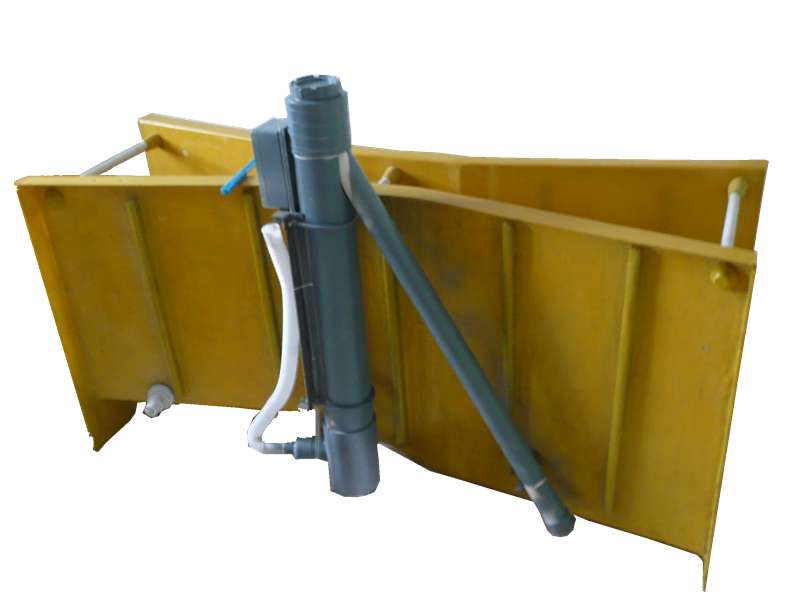

A tapered drill string is characterized by its non-uniform diameter, with the diameter gradually decreasing from the top to the bottom. Unlike conventional drill strings, which maintain a consistent diameter throughout, tapered drill strings are designed to maximize strength, minimize weight, and optimize hydraulic performance. The design typically features a larger cross-section at the surface, which is beneficial for handling the heavy loads and stress incurred during drilling. As the string descends, the diameter tapers down, reducing the weight and allowing for more efficient penetration into the earth’s crust.

Key Design Features

1. Weight Reduction One of the most significant advantages of a tapered drill string is that it effectively reduces the overall weight that the drilling rig must support. By minimizing the weight in the lower sections, operators can use lighter rigs and save on fuel costs, without compromising on drilling performance.

2. Increased Strength The design of tapered drill strings optimizes material usage, providing strength where it is most needed. The larger diameter section can better withstand the high tensile and torsional stresses encountered during drilling, while the tapering section alleviates excess weight.

3. Improved Hydraulic Efficiency With a varying diameter, tapered drill strings can enhance mud flow and cuttings evacuation, essential for maintaining efficient drilling operations. This hydraulic efficiency results in better cooling of the drill bit and ensures that the hole remains clean, thereby facilitating faster drilling rates.

4. Versatility in Drilling Applications Tapered drill strings can be designed for different types of drilling operations, including vertical, horizontal, and directional drilling. This versatility makes them an appealing choice for operators working in varied geological conditions.

tapered drill string a closer look at its design and applications

Applications of Tapered Drill Strings

The applications of tapered drill strings are diverse, spanning various sectors of the energy industry

1. Oil and Gas Exploration In oil and gas exploration, the capability to drill deeper and efficiently through tough geological formations is paramount. Tapered drill strings allow for better performance in harsh environments, making them ideal for exploratory drilling.

2. Geothermal Energy The geothermal industry also benefits from the use of tapered drill strings, particularly in deep well applications where high temperatures and pressures are present. Their ability to withstand extreme conditions while maintaining efficiency makes them suitable for geothermal wells.

3. Mining Operations Tapered drill strings are increasingly used in mining operations to reach mineral deposits located far deeper underground. The efficiency and strength of these drill strings bring significant advantages to the mining sector, especially in complex geological settings.

4. Environmental Drilling In environmental projects, where precision drilling is required, tapered drill strings can aid in reducing the risk of contamination by minimizing the disturbance of surrounding soil and rock. This is particularly crucial in projects involving underground storage or restoration work.

Conclusion

Tapered drill strings represent a significant leap forward in drilling technology, combining strength, efficiency, and versatility in design. As the demands of the energy industry evolve, smooth and cost-effective drilling solutions become increasingly important. The adoption of tapered drill strings not only enhances drilling performance but also contributes to safer and more sustainable practices in oil, gas, and mineral extraction. As technology continues to advance, we can expect to see further innovations that leverage the advantages of tapered drill strings, driving the industry towards a more efficient and economically viable future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025