-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 24, 2025 02:31

Back to list

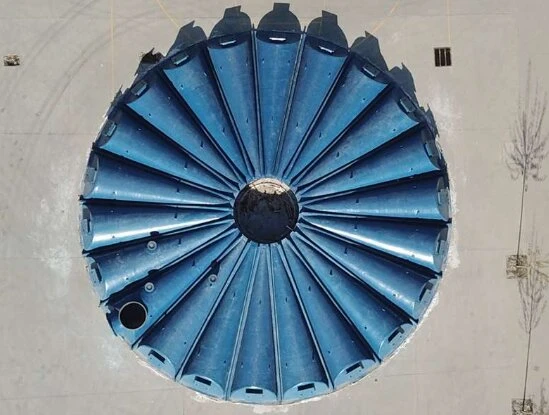

tapered drill string a closer look at its design and applications

Tapered drill strings have emerged as essential tools within the realm of oil and gas exploration, mining, and geotechnical drilling. They represent a sophisticated evolution in drill string design that addresses the nuanced demands of modern drilling environments. This article delves into the intricacies of tapered drill strings, their innovative design, and the practical applications that make them a valuable asset for drilling operations worldwide.

- Oil and Gas Exploration The complex geological formations encountered in oil and gas fields necessitate drilling solutions that can adapt to varying conditions. Tapered drill strings provide the flexibility needed for exploring both conventional and unconventional reserves, reducing the frequency of costly string replacements. - Mining Operations In mining, where exploration requires penetration through extremely hard rock or stratified layers, the tailored stress distribution of tapered drill strings ensures reliability and longevity, crucial for reducing operational downtime. - Geotechnical Drilling For civil engineering projects, such as tunneling and foundation construction, tapered drill strings offer the precision and adaptability needed to maneuver through diverse geological conditions, ensuring the structural integrity and safety of construction projects. Authentic Experience and Industry Trust Professionals working with tapered drill strings often cite the substantial reduction in overall drilling costs and time. This is achieved through their adaptability and reduced wear and tear compared to traditional straight drill strings. The ability to drill faster and deeper with fewer interruptions enhances project timelines and elevates the trust between service providers and clients. Challenges and Future Prospects Despite their benefits, tapered drill strings are not without challenges. Manufacturing requires precise engineering processes, and the initial cost can be higher compared to conventional drill strings. However, advances in manufacturing technology and materials science are paving the way for more cost-effective production methods. Moreover, the continuous research and development within the field aim to incorporate smart technologies into tapered drill strings. Future innovations may include sensors for real-time data analysis, further optimizing drilling efficiency and safety. In sum, tapered drill strings are at the forefront of advancing drilling technologies, meeting the growing demands of the energy sector and beyond. Their sophisticated design and diverse applications underscore a commitment to improving drilling efficiency and reliability, positioning them as a foundational element of modern drilling operations. As industries continue to push the boundaries of exploration, tapered drill strings will undoubtedly remain pivotal in these endeavors.

- Oil and Gas Exploration The complex geological formations encountered in oil and gas fields necessitate drilling solutions that can adapt to varying conditions. Tapered drill strings provide the flexibility needed for exploring both conventional and unconventional reserves, reducing the frequency of costly string replacements. - Mining Operations In mining, where exploration requires penetration through extremely hard rock or stratified layers, the tailored stress distribution of tapered drill strings ensures reliability and longevity, crucial for reducing operational downtime. - Geotechnical Drilling For civil engineering projects, such as tunneling and foundation construction, tapered drill strings offer the precision and adaptability needed to maneuver through diverse geological conditions, ensuring the structural integrity and safety of construction projects. Authentic Experience and Industry Trust Professionals working with tapered drill strings often cite the substantial reduction in overall drilling costs and time. This is achieved through their adaptability and reduced wear and tear compared to traditional straight drill strings. The ability to drill faster and deeper with fewer interruptions enhances project timelines and elevates the trust between service providers and clients. Challenges and Future Prospects Despite their benefits, tapered drill strings are not without challenges. Manufacturing requires precise engineering processes, and the initial cost can be higher compared to conventional drill strings. However, advances in manufacturing technology and materials science are paving the way for more cost-effective production methods. Moreover, the continuous research and development within the field aim to incorporate smart technologies into tapered drill strings. Future innovations may include sensors for real-time data analysis, further optimizing drilling efficiency and safety. In sum, tapered drill strings are at the forefront of advancing drilling technologies, meeting the growing demands of the energy sector and beyond. Their sophisticated design and diverse applications underscore a commitment to improving drilling efficiency and reliability, positioning them as a foundational element of modern drilling operations. As industries continue to push the boundaries of exploration, tapered drill strings will undoubtedly remain pivotal in these endeavors.

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025