-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

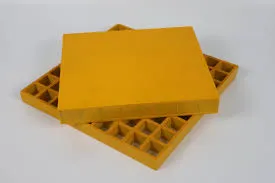

tools for drilling through rock in tunnels, specifically designed

Tools for Drilling Through Rock in Tunnels Specifically Designed Solutions

Drilling through rock to create tunnels is one of the most challenging tasks in engineering and construction. It requires not only advanced technology but also specialized tools designed to handle the unique challenges posed by different types of rock formations. These tools must be robust, efficient, and capable of operating under varying geological conditions.

One of the most widely used tools in tunnel drilling is the tunnel boring machine (TBM). These machines are specifically designed for excavating tunnels through various types of rock and soil. A TBM consists of a rotating cutting head that grinds the rock as it moves forward, while a conveyor system removes the excavated material. The precision and efficiency of TBMs significantly reduce the amount of time and manpower needed for tunneling projects compared to traditional drilling methods. Additionally, they can operate in highly populated urban areas with minimal disruption above ground.

Another important category of tools for tunnel drilling is rock drills. These are used for creating holes for explosives or for anchoring rock bolts in underground projects. Hydraulic or pneumatic rock drills can achieve high penetration rates and are particularly effective in hard rock conditions. Their portability allows they can be used in confined spaces, making them invaluable in tunnel construction, where space is often at a premium.

tools for drilling through rock in tunnels, specifically designed

In addition to drilling machines, specific cutting tools play a vital role in the tunneling process. These may include diamond bits, carbide-tipped bits, and various forms of rotary drilling tools. Diamond bits, while more expensive, are exceptionally durable and capable of cutting through the hardest of materials. Their use can significantly decrease drilling time and increase the overall efficiency of tunneling operations.

Moreover, advances in technology have led to the development of electronic and robotic systems that can assist in the drilling process. These systems can monitor rock conditions in real time, allowing for immediate adjustments to the drilling parameters. This capability is essential for navigating unexpected geological features that may be encountered during tunnel construction.

To further enhance safety and efficiency, many modern tunneling tools integrate advanced cutting-edge features such as real-time data analytics, which optimize performance and predict wear and tear. This predictive maintenance approach helps in minimizing Downtime and reducing overall project costs.

In conclusion, the tools for drilling through rock in tunnels are specialized and engineered for the demanding conditions of underground construction. By selecting the right combination of TBMs, rock drills, and cutting tools, along with leveraging advanced technology, engineers can ensure that tunneling projects are completed efficiently, safely, and within budget. As projects continue to grow in complexity, the development and implementation of more sophisticated tools will remain essential in the field of underground construction.