-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Tools for Efficient Rock Drilling in Tunnel Construction Applications

Tools for Drilling Through Rock in Tunnels Specifically Designed for Efficiency and Safety

Drilling through rock is one of the most challenging tasks in tunnel construction, where precision, efficiency, and safety are paramount. The main tools utilized in this process are specifically designed to handle the unique challenges posed by geological conditions. This article explores these tools, their functionalities, and the technology behind them that makes them indispensable for underground excavation projects.

The Importance of Specialized Tools

Drilling in rock requires specialized tools that can withstand significant stress and wear, due to the density and hardness of various rock types. The complexity of tunneling projects entails that equipment must not only be robust but also versatile enough to address varying geological conditions. The selection of the right tools can improve efficiency while reducing the risk associated with tunnel construction.

Drilling Rigs

At the forefront of tunnel drilling are the drilling rigs, which come in various sizes and configurations depending on the project requirements. Two primary types of rigs are commonly used surface drilling rigs and underground drilling rigs. Surface drilling rigs are primarily employed for initial exploration and can be fitted with various drill bits, depending on the rock type.

On the other hand, underground drilling rigs are designed to operate in confined spaces. These rigs are often compact and equipped with advanced navigation systems to ensure precise drilling. Air-powered or electric-powered systems are favored for their efficiency and reduced environmental impact, particularly in sensitive areas.

Drill Bits

Drill bits are crucial components in the drilling process. They come in various designs to cater to different rock types, and the choice of bit can significantly influence the speed and effectiveness of the drilling operation.

1. Tricone Bits These bits are widely used in soft to medium rock formations. They consist of three rotating cones that crush the rock. Tricone bits are known for their durability and ability to maintain drilling accuracy.

tools for drilling through rock in tunnels, specifically designed

2. Diamond Bits For extremely hard rock formations, diamond drill bits are considered the gold standard. They are embedded with synthetic or natural diamonds, allowing them to cut through the toughest materials with relative ease. Their long life and effectiveness make them a popular choice for critical tunnel projects.

3. Tungsten Carbide Bits These bits are ideal for abrasive rock conditions. Tungsten carbide is known for its hardness; thus, bits made from this material can handle extensive wear and tear while providing high cutting efficiency.

Tunnel Boring Machines (TBMs)

For large-scale projects, Tunnel Boring Machines (TBMs) have revolutionized the approach to tunnel excavation. TBMs are massive, sophisticated machines that can efficiently excavate tunnel paths through various types of materials, including rock and soil.

These machines feature rotating cutter heads that can be equipped with multiple types of cutting tools, including disc cutters and heavy-duty drill bits, allowing them to adapt to the geology encountered. One of the key advantages of TBMs is their ability to install tunnel linings as they progress, thereby enhancing safety and reducing the amount of post-excavation work required.

Innovations in Drilling Technology

The field of rock drilling is continually evolving, with advancements in technology leading to improved safety and efficiency. The integration of automation and real-time monitoring systems into drilling operations is a notable development. These technologies allow operators to remotely control the drilling process and monitor conditions in real time, thereby minimizing risks and enhancing decision-making capabilities.

Moreover, advancements in materials science have led to the development of stronger, lighter materials for drill bits and rigs, resulting in improved operational efficiency. Noise and dust suppression technologies have also been integrated into modern drilling tools, addressing environmental concerns associated with tunnel construction.

Conclusion

Tunneling and rock drilling require specific tools and equipment designed to handle the unique challenges of excavating underground structures. The combination of state-of-the-art drilling rigs, specialized drill bits, innovative tunneling machines, and the latest technology ensures that these operations can be conducted more efficiently and safely than ever before. As the demand for tunnel construction continues to grow globally, the importance of utilizing adequately designed tools tailored to different geological conditions cannot be overstated. The future of tunnel drilling looks promising, driven by ongoing innovations that foster a safer and more efficient excavation process.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

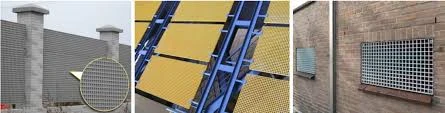

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025