-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

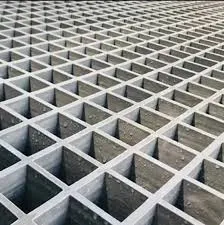

tools for drilling through rock in tunnels, specifically designed ...

Tools for Drilling Through Rock in Tunnels A Comprehensive Overview

Drilling through rock to create tunnels is a monumental task that requires advanced tools and techniques. As urbanization increases and the demand for infrastructure rises, the importance of efficient tunneling methods becomes paramount. This article explores the various tools specifically designed for drilling through rock in tunnels, focusing on their functionality, applications, and innovative advancements.

The Importance of Tunneling

Tunneling plays a critical role in modern engineering. It enables the construction of transport systems, water supply routes, and utilities beneath the surface. The complexity of rock geology beneath urban and rural landscapes poses significant challenges, necessitating the use of specialized tools. The primary objective is to ensure safety, efficiency, and cost-effectiveness while minimizing disturbance to the surrounding environment.

Drilling Techniques

1. Conventional Drilling

Conventional drilling techniques utilize rotary drills that are equipped with carbide-tipped drill bits. These drills operate by rotating the bit against the rock, allowing it to penetrate and remove material. The size and design of the bit vary based on the type of rock being drilled. For instance, softer sedimentary rocks may require different tools compared to harder igneous rocks. Conventional drilling is widely used due to its simplicity and effectiveness, though it can be slower in harder materials.

2. Continuous Miner Systems

Continuous miners are a staple in underground mining operations and are increasingly being adapted for tunneling projects. These machines operate by using a large rotating drum equipped with sharp, heavy-duty bits that can cut through rock as they advance. One of the significant advantages of continuous miners is their ability to extract material continuously, reducing the need for additional drilling and blasting activities, which can be time-consuming and hazardous.

3. Tunnel Boring Machines (TBMs)

Tunnel Boring Machines (TBMs) are among the most advanced tools used for tunneling. These massive, complex machines can efficiently bore through various types of rock and soil. TBMs come in different designs, including Earth Pressure Balanced (EPB) and Slurry Shield types, which are ideal for different geological conditions. The use of TBMs not only increases the speed of tunnel construction but also enhances safety by minimizing ground disturbance and providing a protective shield for workers.

tools for drilling through rock in tunnels, specifically designed ...

Innovations in Drilling Technology

The tunneling industry is witnessing significant technological advancements that enhance drilling efficiency and safety. Some of the notable innovations include

1. Automation and Robotics

The integration of automation and robotics in tunneling operations is revolutionizing the industry. Automated systems can monitor drilling conditions in real-time and adjust parameters such as speed and pressure accordingly. This not only improves the precision of drilling but also reduces reliance on manual labor, enhancing safety.

2. Smart Drilling Technologies

Smart drilling technologies involve the use of sensors and data analytics to optimize drilling processes. These tools monitor parameters like temperature, vibration, and resistance, providing valuable insights into the rock conditions and helping engineers make informed decisions in real-time.

3. Advanced Material Science

The development of new materials for drill bits and drilling systems is enhancing performance and durability. For example, materials like polycrystalline diamond compact (PDC) provide superior hardness and wear resistance, allowing for faster and more efficient drilling in hard rock formations.

Conclusion

The challenges associated with drilling through rock in tunnel construction require a combination of traditional techniques and modern innovations. From conventional drills to sophisticated TBMs and smart technologies, the tools available for tunneling are continually evolving. As infrastructure demands grow and urban areas expand, the need for efficient and safe tunneling methods will only become more critical. Investing in advanced tunneling tools and techniques is essential for meeting these challenges and ensuring the infrastructure of the future is built solidly beneath the earth's surface. The continuous development in this field promises to make tunneling safer and more efficient, paving the way for the next generation of engineering marvels.