-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 18, 2025 10:07

Back to list

Transport Tanks

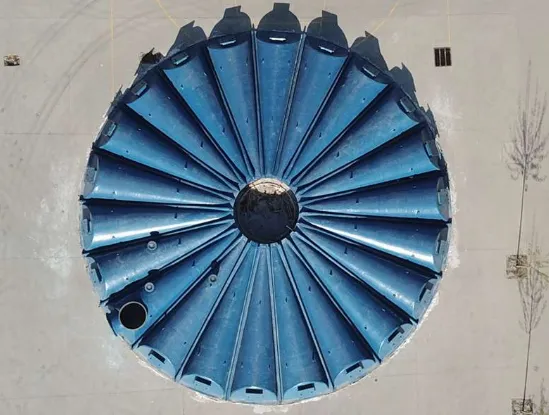

Drilling through rock in tunnel construction requires specialized tools that combine precision, durability, and efficiency. The evolution of these tools reflects advancements in engineering and material science, enabling tunneling projects to become more streamlined and cost-effective. Here we explore some of the latest innovations in rock drilling technology, focusing on what makes specific tools viable choices for different tunnel environments.

For comprehensive rock excavation in tunnel construction, integrating these tools with electronic monitoring systems has become a standard practice. Modern drilling rigs are often equipped with sensors that provide real-time data on drill performance, rock conditions, and alignment. These systems not only enhance productivity by minimizing downtime but also improve safety by predicting equipment failures before they occur. The data collected can be analyzed to optimize drill bit life, energy consumption, and overall system performance, making these digital enhancements pivotal in large-scale tunneling. Environmental considerations also influence the development and choice of drilling tools. As construction projects negotiate stricter regulatory landscapes and sustainability goals, tool manufacturers focus on reducing the ecological footprint of their equipment. This involves designing components that minimize noise and vibration, reduce water and chemical usages, and improve energy efficiency. Electrically powered drills have begun to replace traditional diesel engines in certain applications, offering a cleaner alternative without sacrificing performance metrics. Finally, the expertise required to operate advanced rock drilling tools is crucial in realizing their full potential. Companies invest in training programs to ensure that their operators can effectively wield these tools, optimizing the balance between human skill and technological advancement. Frequent workshops and certification courses offer hands-on experiences, ensuring that workers are not only familiar with the latest tools but are also proficient in applying best practices for maintenance and safety. In conclusion, the array of tools designed for rock drilling in tunnels showcase the convergence of engineering innovation, environmental stewardship, and human capability. They reflect an industry committed to pushing the boundaries of what is possible in subterranean construction, always with an eye toward improving efficiency, safety, and sustainability. For anyone involved in tunnel construction, understanding the nuances of these tools not only enhances project outcomes but also solidifies a reputation for expertise and reliability in a competitive field. By adopting the latest technologies and best practices, companies can continue to break new ground—literally and figuratively—in the realm of tunnel construction.

For comprehensive rock excavation in tunnel construction, integrating these tools with electronic monitoring systems has become a standard practice. Modern drilling rigs are often equipped with sensors that provide real-time data on drill performance, rock conditions, and alignment. These systems not only enhance productivity by minimizing downtime but also improve safety by predicting equipment failures before they occur. The data collected can be analyzed to optimize drill bit life, energy consumption, and overall system performance, making these digital enhancements pivotal in large-scale tunneling. Environmental considerations also influence the development and choice of drilling tools. As construction projects negotiate stricter regulatory landscapes and sustainability goals, tool manufacturers focus on reducing the ecological footprint of their equipment. This involves designing components that minimize noise and vibration, reduce water and chemical usages, and improve energy efficiency. Electrically powered drills have begun to replace traditional diesel engines in certain applications, offering a cleaner alternative without sacrificing performance metrics. Finally, the expertise required to operate advanced rock drilling tools is crucial in realizing their full potential. Companies invest in training programs to ensure that their operators can effectively wield these tools, optimizing the balance between human skill and technological advancement. Frequent workshops and certification courses offer hands-on experiences, ensuring that workers are not only familiar with the latest tools but are also proficient in applying best practices for maintenance and safety. In conclusion, the array of tools designed for rock drilling in tunnels showcase the convergence of engineering innovation, environmental stewardship, and human capability. They reflect an industry committed to pushing the boundaries of what is possible in subterranean construction, always with an eye toward improving efficiency, safety, and sustainability. For anyone involved in tunnel construction, understanding the nuances of these tools not only enhances project outcomes but also solidifies a reputation for expertise and reliability in a competitive field. By adopting the latest technologies and best practices, companies can continue to break new ground—literally and figuratively—in the realm of tunnel construction.

Next:

Related Products