-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

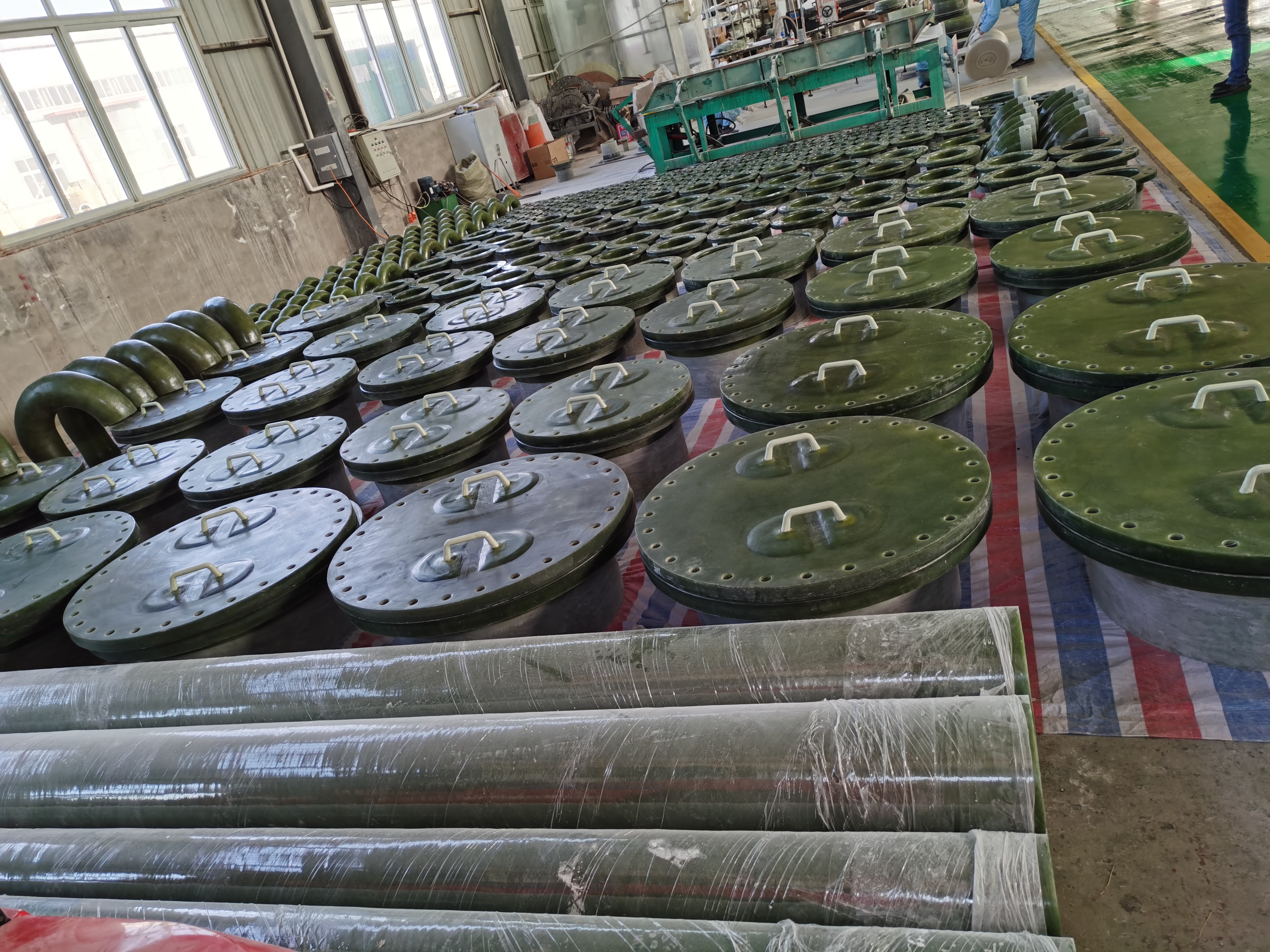

Tungsten Carbide Drilling Bits for Improved Mining Efficiency and Performance

Tungsten Carbide Mining Button Bits for Enhanced Drilling

In the world of mining and drilling, efficiency, durability, and performance are paramount. One of the critical components that determine the success of drilling operations is the type of drill bit used. When it comes to robust performance in challenging conditions, tungsten carbide mining button bits stand out as a top choice for many operations. These high-performance components are engineered to improve drilling efficiency, and their unique properties make them integral in various mining applications.

What are Tungsten Carbide Mining Button Bits?

Tungsten carbide mining button bits are specialized drilling tools designed for rock cutting. They consist of a steel body embedded with buttons made from tungsten carbide—a dense and extremely hard material. This combination allows the bits to withstand high pressures and abrasive conditions typically found during drilling operations. The hard carbide buttons are shaped in a manner that optimizes penetration and enhances cutting efficiency, making them suitable for a variety of geological formations.

Advantages of Tungsten Carbide Mining Button Bits

The use of tungsten carbide mining button bits offers several advantages that contribute to enhanced drilling performance

1. Durability Tungsten carbide is known for its exceptional hardness, which allows these bits to maintain their cutting edges despite prolonged use in tough environments. They resist wear and tear better than standard steel bits, leading to longer operational life and reduced downtime.

2. Efficiency The design of the button bits facilitates efficient rock-breakage patterns, which enhances the rate of penetration (ROP). This efficiency allows mining operations to complete drilling tasks more quickly, maximizing productivity and minimizing costs.

tungsten carbide mining button bits for enhanced drilling ...

3. Versatility Tungsten carbide bits can effectively drill through various rock types, including hard, dense formations. This versatility makes them ideal for a range of applications, from exploration drilling to production drilling in the mining sector.

4. Heat Resistance The high melting point of tungsten carbide contributes to its resistance to heat generation during drilling. This feature is crucial, as excessive heat can weaken other materials and cause failures. The ability of tungsten carbide to maintain its integrity at elevated temperatures further enhances its performance in demanding drilling environments.

5. Cost-Effectiveness Although tungsten carbide bits may have a higher initial cost compared to conventional bits, their longevity and efficiency translate into cost savings over time. Fewer replacements and reduced operational downtime lead to lower overall expenses for mining companies.

Applications in Mining

Tungsten carbide mining button bits are widely used in various mining operations, particularly in hard rock mining, where traditional drill bits may fail to perform effectively. Common applications include

- Quarrying These bits are used to extract minerals from quarries, providing the necessary durability to cut through different types of rock. - Tunneling In underground mining and tunneling projects, tungsten carbide bits make it easier to navigate through hard geological formations, improving both safety and speed. - Oil and Gas Extraction In the oil and gas industry, drilling through tough sedimentary and igneous rock formations requires high-performance bits. Tungsten carbide mining button bits meet these demands effectively.

Conclusion

As the mining industry continues to evolve and face new challenges, the importance of innovative drilling technology cannot be overstated. Tungsten carbide mining button bits represent a significant advancement in drilling technology, offering enhanced performance, durability, and efficiency. Their ability to withstand harsh conditions while maintaining performance standards makes them an invaluable tool for mining operations. As companies seek to optimize their drilling practices and improve productivity, investing in high-quality tungsten carbide bits is a strategic move that can yield substantial returns in both operational efficiency and cost savings. As the demands of the mining sector grow, the role of advanced materials and technologies like tungsten carbide will undoubtedly become increasingly critical.