-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Tungsten Carbide Mining Bits for Improved Drilling Performance and Efficiency

Tungsten Carbide Mining Button Bits for Enhanced Drilling

In the realm of mining and drilling, the efficiency and effectiveness of operations greatly depend on the tools used. Among these tools, tungsten carbide mining button bits have emerged as a game-changer for enhancing drilling performance. Known for their durability, resilience, and superior performance, these specialized bits are integral to the mining industry, offering a multitude of advantages.

Understanding Tungsten Carbide

Tungsten carbide is a robust material created by combining tungsten and carbon. It is known for its hardness, making it an ideal choice for applications requiring high wear resistance. In the context of mining, tungsten carbide is utilized in the production of button bits that penetrate hard rock, allowing for faster and more efficient drilling. These bits display excellent resistance to abrasion and impact, extending their lifespan and reducing the frequency of replacements.

Design and Functionality

Tungsten carbide mining button bits are expertly designed with a series of steel bodies that house the tungsten carbide buttons. The buttons are strategically placed to maximize the cutting action during the drilling process. This design allows for a more efficient transfer of energy from the drill rig to the rock, resulting in faster penetration rates and minimal energy loss.

One of the key features of these bits is their tapered or fixed screw design, allowing them to be used across various drilling applications. Whether for exploration drilling, production drilling, or other geological sampling, tungsten carbide button bits can adapt to the specific requirements of the job at hand.

Enhanced Drilling Performance and Efficiency

tungsten carbide mining button bits for enhanced drilling

The most significant advantage of tungsten carbide button bits lies in their ability to enhance drilling performance. The hardness of tungsten carbide ensures that the bits can withstand extreme pressure and heat, which is unavoidable when drilling through tough geological formations. The increased durability means that these bits can drill deeper and maintain their integrity over longer periods, leading to higher productivity and reduced downtime.

Additionally, the cutting efficiency of tungsten carbide means that less time is needed to achieve the desired depths. This not only saves time but also reduces fuel consumption and operational costs. Operators can achieve more with less, allowing for improved resource management and profitability in mining operations.

Versatility in Applications

Tungsten carbide mining button bits are versatile and can be used in various types of drilling operations, including rotary drilling, raise boring, and directional drilling. Their adaptability to different geological conditions makes them suitable for a wide range of mining environments, from hard rock to softer sedimentary formations. This versatility ensures that mining companies can rely on tungsten carbide bits for all their drilling needs.

Environmental Impact

In today's environmentally conscious world, the efficiency and durability of tungsten carbide button bits also contribute positively to sustainability efforts in mining. Enhanced drilling performance means less energy consumption and reduced waste, aligning with global initiatives to lower the environmental footprint of mining operations. By selecting durable, high-performance tools, companies can minimize their resource usage while maximizing output.

Conclusion

In conclusion, tungsten carbide mining button bits represent a significant advancement in drilling technology. Their unique properties, including unmatched hardness and wear resistance, contribute to enhanced drilling performance across various applications. As mining operations become increasingly focused on efficiency, cost-effectiveness, and sustainability, the adoption of tungsten carbide bits is likely to grow. By investing in high-quality drilling tools, mining companies can not only improve productivity but also contribute positively to the industry's overall impact on the environment. In a world where every second and every penny counts, tungsten carbide mining button bits are poised to lead the way toward more efficient and responsible drilling practices.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

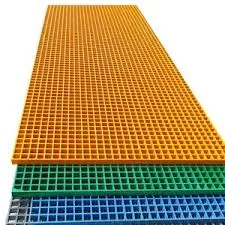

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025