-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

vessels and tanks

Vessels and Tanks Essential Components of Industrial Storage and Transport

In the expansive landscape of industrial operations, vessels and tanks play a crucial role in the storage, transport, and processing of various liquids and gases. These structures are pivotal for a range of industries, including chemical manufacturing, petroleum refining, food processing, and pharmaceuticals. Understanding their design, function, and applications can shed light on their importance in modern industrial systems.

Types of Vessels and Tanks

At the core of industrial storage solutions are two primary types of containers vessels and tanks. While both serve similar purposes, they cater to different requirements based on their design and function.

Tanks are typically large, open containers used primarily for the storage of liquids. They can be above-ground or underground, depending on the application and regulatory considerations. Common materials for construction include steel, concrete, and fiberglass, each chosen based on the properties of the stored substance. For instance, steel tanks are preferred for their durability and robustness in storing hydrocarbons, whereas fiberglass tanks are often utilized for corrosive chemicals due to their resistance to chemical reactions.

Vessels, on the other hand, are often designed to withstand high pressure and temperature. They encompass a broader range of applications that include reactors, separators, and pressure vessels. For example, a pressure vessel might be used in the storage of compressed gases or for carrying out chemical reactions at elevated pressures. Unlike tanks, vessels often involve complex engineering designs due to the significant stresses they must endure.

Applications Across Industries

vessels and tanks

The significance of vessels and tanks transcends mere storage

. In the chemical industry, for example, tanks store raw materials such as solvents, acids, and bases, while pressure vessels facilitate crucial processes like distillation and reaction under controlled conditions. In the petroleum sector, large tanks are critical for the bulk storage of crude oil and refined products, acting as a buffer against market fluctuations.In the food and beverage industry, tanks serve to store and ferment liquids, such as wine or beer, allowing for the maturation process that enhances flavor. The pharmaceutical sector also relies heavily on controlled storage tanks and vessels to ensure that sensitive compounds are stored under meticulous conditions to maintain their efficacy.

Safety and Regulations

Safety is paramount in the design and operation of vessels and tanks. Given the potential hazards of storing volatile substances, adherence to strict regulatory standards is essential. Organizations such as the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA) set guidelines that dictate the design, maintenance, and operational procedures for these containers. Regular inspections, maintenance schedules, and safety training are integral components of successful tank and vessel management.

Innovations and Future Trends

As industries evolve, so do the technologies and materials used in the construction of vessels and tanks. Innovations such as smart sensors for monitoring structural integrity and pressure levels are becoming commonplace. Furthermore, advancements in materials science may lead to lighter and more resistant materials that can handle the aggressive environments often associated with industrial storage.

In conclusion, vessels and tanks are indispensable elements of modern industry, facilitating the safe and efficient storage and transport of vital materials. Their continued evolution, driven by technological advancements and regulatory requirements, will play an essential role in supporting a diverse array of sectors, ensuring that they operate safely and sustainably in an ever-changing landscape.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

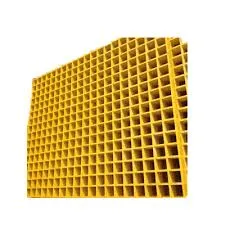

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025