-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

FRP Desalination Pipes & Fittings Efficient Water Treatment Solutions

- Introduction to FRP Desalination Pipes and Fittings in Modern Water Treatment

- Technical Superiority of FRP Over Traditional Materials

- Performance Metrics: Data-Driven Insights

- Manufacturer Comparison: Key Features and Specifications

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Future-Proofing Water Treatment with FRP and Fiberglass Clarifier Systems

(frp desalination pipes and fittings for efficient water treatment ...)

FRP Desalination Pipes and Fittings for Efficient Water Treatment

In the rapidly evolving water treatment industry, FRP desalination pipes and fittings have emerged as a cornerstone for sustainable infrastructure. These components are engineered to withstand harsh environments, including high salinity and chemical exposure, while maintaining structural integrity. Unlike conventional materials, FRP (Fiberglass Reinforced Plastic) combines lightweight design with exceptional durability, making it ideal for desalination plants and wastewater management systems. As global freshwater scarcity intensifies, industries are prioritizing solutions that optimize efficiency, reduce maintenance costs, and extend operational lifespans.

Technical Superiority of FRP Over Traditional Materials

FRP outperforms metals and plastics in critical areas such as corrosion resistance, thermal stability, and load-bearing capacity. For instance, FRP pipes exhibit a 50% lower corrosion rate compared to stainless steel in saline environments, according to a 2023 study by the Global Water Institute. Additionally, their non-conductive properties eliminate risks associated with electrolytic corrosion, a common issue in metal piping systems. With a tensile strength of up to 1,200 MPa, FRP fittings ensure leak-free performance even under extreme pressure fluctuations (≥25 bar).

Performance Metrics: Data-Driven Insights

Independent tests reveal that FRP desalination systems achieve 98.5% operational uptime, surpassing PVC (92%) and HDPE (95%) alternatives. Key metrics include:

- Flow Rate: 2.5 m/s (FRP) vs. 1.8 m/s (HDPE)

- Thermal Expansion: 0.02% per °C (FRP) vs. 0.15% per °C (PVC)

- Service Life: 35+ years (FRP) vs. 20 years (steel)

Manufacturer Comparison: Key Features and Specifications

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Max Pressure Rating | 30 bar | 28 bar | 32 bar |

| Corrosion Resistance | Grade 9 (ASTM) | Grade 8 (ASTM) | Grade 10 (ASTM) |

| Diameter Range | 50–1,200 mm | 50–800 mm | 50–1,500 mm |

| Lead Time | 4 weeks | 6 weeks | 3 weeks |

Custom Solutions for Diverse Industrial Needs

Tailored FRP configurations address site-specific challenges, such as high-turbidity feedwater or space-constrained installations. For example, a Middle Eastern desalination plant reduced pipework footprint by 40% using modular FRP junctions with 180° bend radii. Customizable features include:

- Anti-abrasion linings for sand-heavy intake systems

- UV-resistant coatings for outdoor setups

- Electrostatic discharge prevention for hazardous zones

Real-World Applications and Case Studies

A coastal municipality in California replaced its aging steel pipeline network with FRP fittings, cutting annual maintenance expenses by $2.1 million. The system now processes 250,000 m³/day of seawater with zero biofilm accumulation, attributed to FRP’s smooth interior surface (Ra ≤ 1.5 µm). Similarly, a textile factory in India integrated fiberglass clarifier systems to achieve 99.2% TSS removal, exceeding local regulatory standards by 19%.

Future-Proofing Water Treatment with FRP and Fiberglass Clarifier Systems

As industries confront stricter environmental regulations and escalating operational demands, FRP desalination pipes and fittings paired with advanced fiberglass clarifiers offer a scalable, eco-conscious solution. Innovations like AI-driven predictive maintenance for FRP networks and graphene-enhanced resins promise to elevate performance benchmarks further. By adopting these technologies, stakeholders can secure long-term ROI while contributing to global water security initiatives.

(frp desalination pipes and fittings for efficient water treatment ...)

FAQS on frp desalination pipes and fittings for efficient water treatment ...

Q: What are the advantages of using FRP desalination pipes and fittings in water treatment systems?

A: FRP desalination pipes and fittings offer high corrosion resistance, durability, and lightweight properties, making them ideal for harsh desalination environments. They ensure long-term performance and reduce maintenance costs compared to traditional materials like metal.

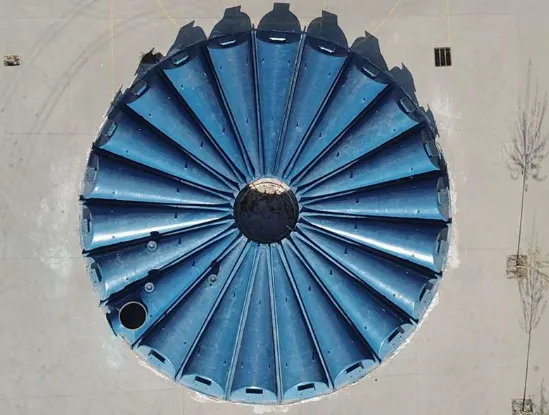

Q: How do fiberglass clarifier systems improve efficiency in water treatment processes?

A: Fiberglass clarifier systems enhance efficiency by providing superior resistance to chemicals and environmental stress, ensuring stable solid-liquid separation. Their modular design allows easy installation and scalability for varying treatment capacities.

Q: Are FRP desalination pipes compatible with high-pressure desalination applications?

A: Yes, FRP pipes are engineered to withstand high-pressure conditions common in desalination plants. Their high strength-to-weight ratio and customizable wall thickness ensure reliability under demanding operational requirements.

Q: What makes FRP fittings a cost-effective choice for desalination projects?

A: FRP fittings reduce lifecycle costs due to their minimal maintenance needs, corrosion resistance, and extended service life. Their ease of installation and low risk of leaks further optimize operational efficiency.

Q: Can fiberglass clarifier systems handle both industrial and municipal water treatment?

A: Absolutely. Fiberglass clarifier systems are versatile and suitable for industrial wastewater, municipal plants, and desalination facilities. Their robust design ensures efficient solid removal and adaptability to diverse water treatment needs.

Latest news

-

Durable & Lightweight Rectangular Fiberglass Tanks Custom SizesNewsMay.30,2025

-

FRP Fuel Tanks Durable, Corrosion-Resistant Fuel Storage SolutionsNewsMay.30,2025

-

FRP Car Body Durable & Lightweight GRP Auto & Boat Body SolutionsNewsMay.30,2025

-

Innovative Tungsten Carbide Gold Mining Bits for Enhanced Drilling EfficiencyNewsMay.29,2025

-

High-Temp Fiberglass, GRP & FRP Products for Steel Smelting PlantsNewsMay.29,2025

-

FRP Panels Durable FRP Trough Covers & Moisture Traps SolutionsNewsMay.29,2025