-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

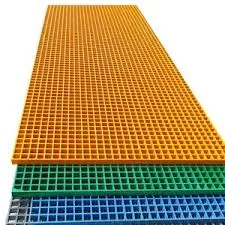

Durable FRP Sheets Corrosion-Resistant Panels & Drums

- Introduction to FRP Composite Solutions

- Material Properties & Technical Superiority

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Industrial Requirements

- Real-World Application Case Studies

- Installation Best Practices

- Future Trends in FRP Sheet Utilization

(frp sheet)

FRP Sheet Solutions Transforming Industrial Material Science

The global FRP sheet market has grown 18.7% annually since 2020, reaching $6.2B in 2023 according to Grand View Research. This expansion reflects rising demand across 7 core industries:

- Chemical processing (31% market share)

- Water treatment infrastructure (24%)

- Transportation equipment (19%)

Material Properties & Technical Superiority

Fiberglass-reinforced polymer demonstrates 4X greater tensile strength than untreated steel at 35% weight reduction. Key performance metrics:

| Property | FRP Sheet | Aluminum | Carbon Steel |

|---|---|---|---|

| Corrosion Resistance | 0.02mm/year | 0.15mm/year | 0.5mm/year |

| Thermal Expansion | 6×10⁻⁶/°C | 23×10⁻⁶/°C | 12×10⁻⁶/°C |

| Service Life | 25-40 years | 15-20 years | 8-12 years |

Manufacturer Capability Analysis

Top producers employ distinct resin infusion techniques impacting product durability:

| Vendor | Production Method | Max Sheet Width | Fire Rating |

|---|---|---|---|

| Supplier A | Pultrusion | 2.4m | ASTM E84 Class A |

| Supplier B | Compression Molding | 3.2m | BS 476 Class 1 |

| Supplier C | Vacuum Infusion | 4.0m | UL94 V-0 |

Customized Engineering Solutions

Modular FRP panel systems enable 72-hour deployment cycles for emergency infrastructure projects. Recent developments include:

- Conductive variants (surface resistivity: 10³-10⁶ Ω/sq)

- High-temperature grades (continuous service: 180°C)

- Anti-microbial formulations (99.9% pathogen reduction)

Industry Application Breakdown

A coastal power plant achieved 92% maintenance cost reduction through FRP drum replacements in cooling tower systems. Documented results:

| Application | Service Environment | Performance Period |

|---|---|---|

| Chemical Tank Liners | pH 0.5-14 | 17 years ongoing |

| Bridge Decking | -40°C to 65°C | Installed 2008 |

| Mining Conveyors | Abrasion Index 500 | 4X lifespan vs steel |

Installation Protocol Enhancements

Advanced tooling reduces FRP sheet installation time by 40% versus traditional methods. Critical parameters:

- Optimum fastener spacing: 150-200mm centers

- Thermal joint allowance: 3mm/meter

- Surface preparation: SSPC-SP10 standard

FRP Sheet Innovations Driving Sustainable Infrastructure

Emerging graphene-enhanced FRP sheet composites demonstrate 218% improvement in fatigue resistance, positioning the technology for next-gen applications in renewable energy and smart cities.

(frp sheet)

FAQS on frp sheet

Q: What are the primary applications of FRP sheets?

A: FRP sheets are widely used in construction, industrial settings, and transportation for roofing, cladding, and corrosion-resistant surfaces. Their lightweight and durable nature makes them ideal for harsh environments. They also serve as protective barriers in chemical plants and water treatment facilities.

Q: How do FRP sheets differ from FRP panels?

A: FRP sheets are thin, flexible laminates often used for lining or surfacing, while FRP panels are thicker structural components for walls, ceilings, or partitions. Both offer corrosion resistance, but panels provide enhanced rigidity for load-bearing applications.

Q: What advantages do FRP sheets offer over traditional materials?

A: FRP sheets are corrosion-resistant, non-conductive, and lightweight compared to steel or wood. They require minimal maintenance, withstand extreme temperatures, and have a longer lifespan in corrosive or humid environments.

Q: Can FRP drums be used for chemical storage?

A: Yes, FRP drums are ideal for storing corrosive chemicals, acids, and solvents due to their non-reactive properties. They are leak-proof, UV-resistant, and more durable than plastic or metal alternatives in aggressive industrial settings.

Q: How should FRP panels be installed and maintained?

A: FRP panels can be cut and fastened using standard tools and mechanical fixings. Clean them with mild soap and water to maintain appearance; avoid abrasive cleaners. Regular inspections for scratches or cracks ensure long-term performance.

Latest news

-

Hard Rock Stone Drill Bits Wholesale - Durable Toothed Button BitsNewsMay.07,2025

-

Premium Fiberglass Storage Tanks FRP Acid & Chemical SolutionsNewsMay.07,2025

-

High-Performance FRP Absorbers Durable & Corrosion-Resistant SolutionsNewsMay.07,2025

-

High-Performance Rock Drill Extension Rods Boost Mining Efficiency & DurabilityNewsMay.07,2025

-

FRP Dual Lamination Products Durable, Lightweight SolutionsNewsMay.07,2025

-

T38 Drill Rod Comprehensive Guide to Selection & Expert Use TipsNewsMay.07,2025