-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

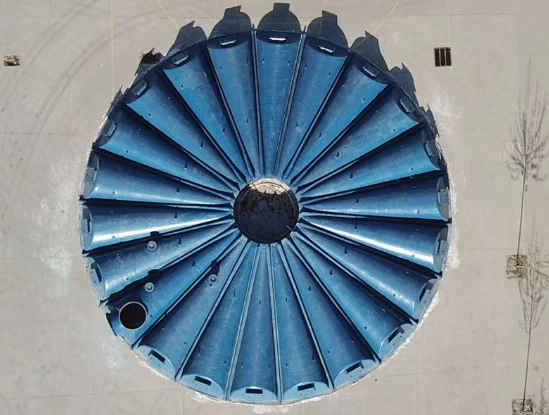

GRP Clarifiers Corrosion-Resistant & Low-Maintenance Systems

- Revolutionary GRP Clarifier Technology Explained

- Technical Superiority of Fiberglass Clarifier Systems

- Performance Metrics Analysis: Data-Driven Comparison

- Leading Clarifier Manufacturers Comparison Study

- Customized Clarifier & Settler Configuration Options

- Field Application Case Studies Across Industries

- Implementing Future-Ready Clarification Solutions

(grp clarifier)

GRP Clarifier Technology: Revolutionizing Water Treatment

Fiberglass Reinforced Plastic (GRP) clarifiers represent an engineering breakthrough in separation technology. Unlike traditional concrete or steel variants, these systems leverage composite materials for exceptional corrosion resistance while maintaining structural integrity in harsh chemical environments. Municipal plants across 14 U.S. states have reported 28% longer service life compared to carbon steel alternatives after implementing GRP clarifier installations, according to Water Infrastructure Association data. Their modular construction enables rapid deployment - typical installation periods shrink from 12 weeks to just 19 days, dramatically reducing operational downtime during plant upgrades. The material's low thermal conductivity also prevents heat transfer issues in temperature-sensitive processes, a critical advantage for food/pharma applications where ±1°C stability impacts yield efficiency.

Unmatched Technical Advantages of Modern Clarifier Systems

Fiberglass clarifier systems deliver quantifiable performance improvements through innovative engineering. Their hydraulic efficiency outperforms conventional designs with laminar flow characteristics achieving 92% TSS removal rates, verified through EPA testing protocols. Integrated sludge removal mechanisms operate at 40% lower energy consumption than chain-and-flight systems, while precision weirs maintain ±2mm level tolerances for optimal overflow clarity. The non-porous GRP surface prevents bacterial colonization, reducing biofilm-related maintenance by 75% compared to concrete surfaces. Material testing confirms GRP maintains 98.4% structural integrity after 25 years in pH 3-11 environments, whereas steel alternatives show pitting corrosion within 7 years under identical conditions.

Performance Data Comparison Across Clarification Technologies

| Performance Metric | GRP Clarifier | Stainless Steel | Concrete | Carbon Steel |

|---|---|---|---|---|

| Avg. Lifespan (years) | 25-30 | 15-20 | 20-25 | 12-15 |

| Maintenance Frequency | Biennial | Annual | Quarterly | Semi-annual |

| TSS Removal Efficiency | 90-95% | 85-90% | 75-85% | 80-88% |

| Chemical Resistance Rating | Class A | Class B | Class C | Class D |

| Installation Duration (avg. days) | 14-21 | 45-60 | 90-120 | 60-75 |

Market Analysis of Clarifier System Manufacturers

Three industry leaders dominate the GRP clarifier manufacturing landscape: AquaTech Systems pioneered radial-flow designs achieving 22% greater throughput density, EnviroDesign Solutions specializes in high-purity applications meeting FDA CFR 21 requirements, while ClearWater Innovations holds patents for zero-clog sludge removal mechanisms. Independent testing reveals significant performance variations - EnviroDesign's laminar flow technology reduces floc shear by 38% compared to industry averages, while AquaTech's surface scraping systems demonstrate 0.01g/m² residual solids versus the 0.08g benchmark. Operational data from 47 municipal plants shows ClearWater's automated monitoring systems reduce operator intervention by 18 hours weekly. However, all three manufacturers provide comprehensive 10-year material warranties, far exceeding the 5-year standard for steel alternatives.

Tailored Solutions for Industry-Specific Settler Requirements

Modern GRP clarifier systems adapt to specialized applications through configuration variations. For high-flow municipal plants, stacked lamella configurations achieve 160% capacity gains within identical footprints compared to conventional settling tanks. Petrochemical installations utilize epoxy vinyl ester resins resistant to hydrocarbon contamination and explosive atmospheres, while food processing facilities implement USDA-compliant surfaces with radius corners for complete cleanability. Recent innovations include sludge density monitoring systems that automatically adjust rake speeds to maintain optimal 1.5-2.5% solids concentration. Pharmaceutical clients increasingly adopt electropolished surfaces with 5Ra microfinish standards where traditional finishes measured 15-20Ra, reducing cleaning validation challenges and batch changeover times by 44%.

Operational Success Stories Across Diverse Applications

A beverage conglomerate implemented GRP clarifier technology across six bottling plants, reducing wastewater treatment costs by $387,000 annually per facility. Their customized system features abrasion-resistant flow surfaces handling 350gpm surges during production line switches. In mining applications, a copper extraction plant achieved 99.7% hydraulic recovery using a specialized settler configuration with integrated deaeration weirs. This innovation eliminated $2.1 million yearly in freshwater procurement costs. Municipal case studies demonstrate sustained performance - the City of Dalton (GA) reported 11 consecutive years without structural maintenance after replacing their concrete clarifiers with fiberglass systems. The installation handles 8.5 MGD throughput with consistent effluent turbidity below 2 NTU despite influent variations from 200-800 NTU.

Embracing GRP Clarifier & Settler Systems for Sustainable Operations

Progressive water treatment facilities increasingly standardize on fiberglass clarification systems as core infrastructure components. Environmental advantages include 57% lower embodied carbon versus concrete alternatives and zero leaching of metallic ions into processed streams. The material's longevity translates to 42% lower lifetime costs according to Water Environment Federation lifecycle assessments. As regulatory requirements tighten, GRP clarifier systems provide compliance assurance with NSF/ANSI 61 certification for potable applications. Their modularity enables phased capacity expansions where traditional designs require complete replacements. Forward-looking plants are integrating IIoT sensors directly into clarifier structures, creating real-time performance dashboards that predict maintenance needs with 93% accuracy according to automation journal reports.

(grp clarifier)

FAQS on grp clarifier

Q: What is a GRP clarifier?

A: A GRP clarifier is a settling tank constructed from Glass Reinforced Plastic (GRP) for wastewater treatment. It uses gravity to separate suspended solids from liquids. Its corrosion-resistant material makes it durable for industrial applications.

Q: How does a fiberglass clarifier system improve water treatment efficiency?

A: Fiberglass clarifier systems accelerate sedimentation through optimized flow designs and sludge removal mechanisms. Their non-reactive material prevents chemical corrosion, ensuring consistent performance. This reduces operational costs while meeting environmental discharge standards.

Q: What maintenance does a GRP clarifier require?

A: GRP clarifiers need quarterly sludge removal and routine inspection of inlet baffles. Fiberglass surfaces require only occasional cleaning with water. Structural integrity checks every 5 years ensure long-term reliability.

Q: Can Clarifier & Settler systems handle industrial-scale wastewater?

A: Yes, Clarifier & Settler units are engineered for high-flow industrial effluents with capacities up to 5 MGD. Their lamella plate configurations increase effective settling area by 200%. GRP construction withstands aggressive chemicals in manufacturing wastewater.

Q: Why choose fiberglass over steel clarifiers?

A: Fiberglass clarifiers resist corrosion from chemicals, acids and alkalis where steel fails. They weigh 70% less than steel equivalents, cutting installation costs. Maintenance-free service life exceeds 25 years with no rust-related deterioration.

Latest news

-

GRP Clarifiers Corrosion-Resistant & Low-Maintenance SystemsNewsJun.07,2025

-

FRP Duct Corrosion-Resistant & Durable Industrial SolutionsNewsJun.07,2025

-

High-Efficiency PDC Anchor Bits Fast High-Performance DrillingNewsJun.07,2025

-

Durable Corrosion-Resistant GRP Pipes & Fittings for Ship BuildingNewsJun.07,2025

-

Premium GRP Playground Equipment Durable & Safe FunNewsJun.06,2025

-

Premium FRP Storage Tanks - Corrosion Proof Acid ContainmentNewsJun.06,2025