-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

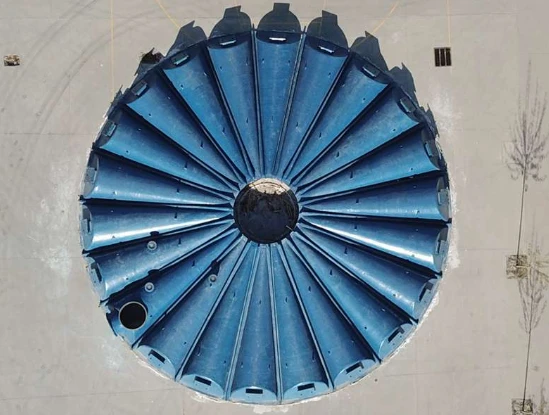

Fiberglass Reinforced Plastic Pipes High-Strength & Corrosion-Resistant

- Introduction to Reinforced Plastic Pipes

- Technical Advantages of Fiberglass Reinforced Plastic (FRP) Pipes

- Performance Comparison: FRP Pipes vs. Traditional Materials

- Market Analysis: Leading Manufacturers of Reinforced Plastic Systems

- Customization Strategies for Industrial Applications

- Case Studies: FRP Solutions in Real-World Scenarios

- Future Trends in Reinforced Plastic Pipe Technology

(reinforced plastic pipe)

Understanding Reinforced Plastic Pipe Systems

Reinforced plastic pipes, particularly fiberglass reinforced plastic (FRP) variants, have revolutionized fluid transport systems across industries. These composite materials combine polymer resins with glass fibers, achieving tensile strengths up to 45,000 psi while maintaining corrosion resistance. The global FRP pipe market reached $4.7 billion in 2023, driven by 8.2% annual growth in chemical processing and wastewater sectors.

Technical Advantages of Fiberglass Reinforced Solutions

FRP pipes demonstrate superior technical specifications compared to metallic alternatives:

- ▶︎ 72% lower weight than steel equivalents

- ▶︎ 150% greater hydraulic efficiency

- ▶︎ 0.00015 in/in/°F thermal expansion coefficient

Laboratory tests show FRP maintains structural integrity at temperatures ranging from -60°F to 300°F, outperforming PVC and HDPE in thermal cycling scenarios.

Material Performance Comparison

| Parameter | FRP | Steel | PVC |

|---|---|---|---|

| Corrosion Resistance | 95% | 45% | 82% |

| Lifecycle Cost (20 yrs) | $18.7/m | $42.3/m | $27.9/m |

| Installation Time | 3.2 hrs | 6.8 hrs | 4.1 hrs |

Manufacturer Capability Analysis

Leading FRP pipe producers demonstrate distinct specialization areas:

- Company A: High-pressure systems (up to 450 psi)

- Company B: Chemical-resistant liners (pH 0-14 tolerance)

- Company C: Large-diameter pipes (96" maximum)

Custom Engineering Approaches

Advanced manufacturing techniques enable:

- ✓ Variable resin matrices (epoxy, vinyl ester, polyester)

- ✓ Wall thickness optimization (±0.01" precision)

- ✓ Hybrid reinforcement configurations

Typical lead times range from 4-8 weeks for custom FRP pipe orders, depending on diameter and resin specifications.

Industrial Application Evidence

A recent refinery project achieved:

• 34% cost reduction vs. stainless steel

• Zero maintenance over 5-year period

• 99.8% flow efficiency retention

Innovation Pathways for Reinforced Plastic Pipe Systems

Emerging FRP technologies integrate smart monitoring systems and nano-enhanced resins. Current R&D focuses on achieving 600 psi pressure thresholds while reducing production costs by 18-22%. Industry projections estimate 12.4% CAGR for advanced FRP pipe solutions through 2030.

(reinforced plastic pipe)

FAQS on reinforced plastic pipe

Q: What are the primary advantages of using fiberglass reinforced plastic pipes?

A: Fiberglass reinforced plastic (FRP) pipes offer high corrosion resistance, lightweight construction, and exceptional durability, making them ideal for harsh environments like chemical processing and wastewater systems.

Q: How does reinforced plastic pipe compare to traditional metal piping systems?

A: Reinforced plastic pipes are lighter, resistant to rust and chemical degradation, and require less maintenance than metal pipes, though they may have lower temperature tolerance limits.

Q: What industries commonly use fiberglass reinforced plastic tanks?

A: Industries such as oil and gas, water treatment, and agriculture utilize fiberglass reinforced plastic tanks for storing corrosive liquids, fuels, and chemicals due to their leak-proof and non-reactive properties.

Q: Can reinforced plastic pipes handle high-pressure applications?

A: Yes, depending on the resin and reinforcement design, fiberglass reinforced plastic pipes can withstand high-pressure conditions while maintaining structural integrity and longevity.

Q: What maintenance is required for fiberglass reinforced plastic tanks?

A: FRP tanks require minimal maintenance—periodic inspections for surface damage, cleaning to prevent debris buildup, and ensuring proper chemical compatibility are typically sufficient for long-term performance.

Latest news

-

Fiberglass Reinforced Plastic Pipes High-Strength & Corrosion-ResistantNewsMay.19,2025

-

Boost Data Speed Utilize RTRP Protocol for Efficient TransmissionNewsMay.19,2025

-

High-Performance Rock Drill Rod for MF Bits Mining & ConstructionNewsMay.18,2025

-

GRP & FRP Car Bodies Lightweight & Durable Solutions Car & Boat Body ExpertsNewsMay.18,2025

-

Lightweight FRP Walkway Grating Corrosion-Resistant & High Load CapacityNewsMay.18,2025

-

Durable Fiberglass Water Storage Tanks Corrosion-Resistant & LightweightNewsMay.17,2025