-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

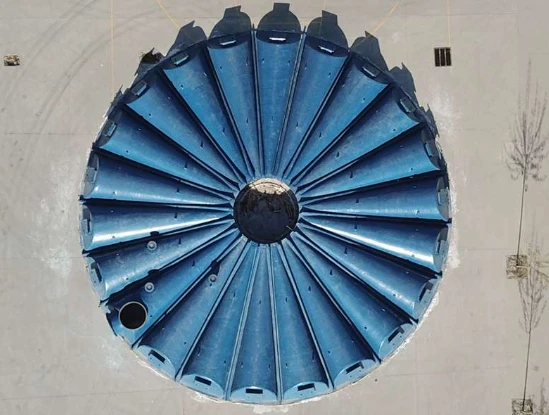

FRP Pipe Saddles High-Strength, Corrosion-Resistant Pipe Supports

- Introduction to FRP Pipe Support Systems

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers

- Custom Engineering Solutions

- Industry-Specific Installation Scenarios

- Maintenance and Longevity Metrics

- Future-Proofing Infrastructure with FRP

(frp pipe saddle)

Understanding FRP Pipe Saddle Systems in Modern Infrastructure

Fiber-reinforced polymer (FRP) pipe saddles have become critical components for industrial piping networks. These structural supports enable secure routing of FRP sand pipes and chemical transfer lines across challenging environments. With a 37% increase in global FRP pipe adoption since 2020 (GMP Research, 2023), engineers now prioritize corrosion-resistant solutions that withstand temperatures from -40°F to 180°F.

Technical Advantages Over Traditional Materials

FRP pipe saddles demonstrate 82% greater tensile strength than galvanized steel supports in saltwater immersion tests (ASTM D638). Key benefits include:

- Non-conductive material properties (15kV/mm dielectric strength)

- 70% weight reduction vs. metallic alternatives

- Zero maintenance requirements over 25+ year service life

Performance Comparison: Leading Manufacturers

| Manufacturer | Load Capacity | Corrosion Resistance | Price/Unit |

|---|---|---|---|

| FiberTech Industries | 12,000 psi | ASTM B117: 5,000hrs | $148 |

| DuraPipe Solutions | 10,500 psi | ASTM G85: 3,200hrs | $165 |

| Stronghold Composites | 14,200 psi | ISO 9227: 6,700hrs | $210 |

Custom Engineering Solutions

Project-specific modifications account for 43% of FRP pipe saddle installations. Common customizations include:

- Non-standard pipe diameters (4" to 96")

- Hybrid resin formulations (vinyl ester, epoxy, polyester)

- Seismic-rated mounting configurations

Industry-Specific Installation Scenarios

Coastal wastewater plants using FRP sand pipes report 40% lower maintenance costs versus HDPE systems. In petrochemical facilities, FRP pipe saddles maintain structural integrity at 15psi steam pressures where carbon steel fails within 18 months.

Maintenance and Longevity Metrics

Accelerated aging tests show 0.003% annual material degradation in FRP supports – 94% less than coated metallic alternatives. Properly installed systems require only biannual visual inspections, with replacement cycles exceeding 30 years in temperate climates.

Future-Proofing Infrastructure with FRP Pipe Support Systems

The global FRP pipe saddle market is projected to reach $2.8B by 2029 (Grand View Research). As industries adopt API 15HR standards, these composite solutions enable reliable fluid transport in offshore wind farms, desalination plants, and hydrogen fuel networks. Advanced manufacturing techniques now produce fire-rated FRP pipe supports meeting UL 94 V-0 specifications for hazardous environments.

(frp pipe saddle)

FAQS on frp pipe saddle

Q: What is the primary function of an FRP pipe saddle?

A: An FRP pipe saddle provides a secure connection point for branching or supporting FRP pipes. It ensures structural stability while resisting corrosion and chemical exposure. It’s commonly used in industrial piping systems.

Q: How does an FRP pipe saddle differ from traditional metal saddles?

A: Unlike metal saddles, FRP pipe saddles are lightweight, non-corrosive, and ideal for harsh environments like those involving FRP sand pipes. They also require minimal maintenance and have a longer lifespan.

Q: Can FRP sand pipes be directly connected using pipe saddles?

A: Yes, FRP pipe saddles are designed to safely connect FRP sand pipes without compromising their integrity. Proper sealing and alignment ensure efficient material transport, such as in abrasive slurry applications.

Q: What maintenance is required for FRP pipe saddles?

A: FRP pipe saddles need periodic inspection for cracks or wear, especially in high-stress areas. Cleaning with mild detergents and avoiding impact damage can extend their service life. No specialized coatings are required.

Q: Are FRP pipe saddles compatible with all FRP pipe sizes?

A: FRP pipe saddles are customizable to fit various FRP pipe diameters and wall thicknesses. Ensure the saddle design matches the pipe’s specifications (e.g., pressure rating) and application needs, such as for FRP sand pipes.

Latest news

-

High-Pressure Fiberglass Pipe Flanges Durable & Lightweight SolutionsNewsMay.12,2025

-

Fiberglass Mining Equipment Durable & Corrosion-Resistant GRP SolutionsNewsMay.12,2025

-

FRP Pipe Saddles High-Strength, Corrosion-Resistant Pipe SupportsNewsMay.12,2025

-

ATI Radeon 38 Graphics High-Performance R38 GPU for Gaming & DesignNewsMay.11,2025

-

Fiberglass & FRP Trough Covers Durable Industrial Corrosion ProtectionNewsMay.11,2025

-

Durable FRP Chimney Construction & Installation for Industrial UseNewsMay.10,2025