-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 04, 2025 10:28

Back to list

Ladders & Handrails

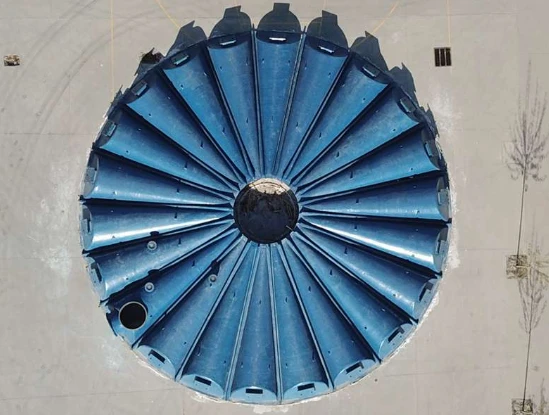

In the vast realm of industrial storage solutions, FRP chemical tanks have emerged as a superior choice for businesses seeking durability, reliability, and cost-effectiveness. Crafted from Fiberglass Reinforced Plastic, these tanks offer unparalleled chemical resistance, setting them apart in environments where harsh chemicals and rigorous conditions are routine.

Trust in a storage solution is paramount, and few other products offer the proven track record of FRP chemical tanks. Their reliability is backed by decades of usage across various industries, with numerous case studies affirming their suitability for demanding chemical storage needs. FRP tanks undergo rigorous testing and meet high industry standards, which bolsters confidence among users about their performance under extreme conditions. When investing in FRP chemical tanks, choosing reputable manufacturers is key to ensuring quality and longevity. Experts recommend working with manufacturers who offer comprehensive support, including installation, maintenance, and after-sales service. This ensures peace of mind, knowing that technical assistance is readily available throughout the tank’s lifetime. In summary, FRP chemical tanks represent a fusion of engineering expertise and environmental forward-thinking. Their adoption signals a commitment to operational excellence and sustainability, qualities that resonate well with both corporate goals and industry standards. For those ready to make a strategic investment in their storage solutions, FRP chemical tanks hold the promise of performance, reliability, and cost savings, positioning them as the optimum choice in today's demanding industrial landscape. Embracing FRP tank technology not only strengthens industrial capabilities but also aligns with the broader sustainability goals many companies are striving to achieve. Whether it’s the need for storing acids, bases, or other challenging substances, FRP chemical tanks are a testament to innovative engineering meeting practical industrial demands.

Trust in a storage solution is paramount, and few other products offer the proven track record of FRP chemical tanks. Their reliability is backed by decades of usage across various industries, with numerous case studies affirming their suitability for demanding chemical storage needs. FRP tanks undergo rigorous testing and meet high industry standards, which bolsters confidence among users about their performance under extreme conditions. When investing in FRP chemical tanks, choosing reputable manufacturers is key to ensuring quality and longevity. Experts recommend working with manufacturers who offer comprehensive support, including installation, maintenance, and after-sales service. This ensures peace of mind, knowing that technical assistance is readily available throughout the tank’s lifetime. In summary, FRP chemical tanks represent a fusion of engineering expertise and environmental forward-thinking. Their adoption signals a commitment to operational excellence and sustainability, qualities that resonate well with both corporate goals and industry standards. For those ready to make a strategic investment in their storage solutions, FRP chemical tanks hold the promise of performance, reliability, and cost savings, positioning them as the optimum choice in today's demanding industrial landscape. Embracing FRP tank technology not only strengthens industrial capabilities but also aligns with the broader sustainability goals many companies are striving to achieve. Whether it’s the need for storing acids, bases, or other challenging substances, FRP chemical tanks are a testament to innovative engineering meeting practical industrial demands.

Next:

Related Products

Latest news

-

FRP Hood Durable & Lightweight Fiberglass Hood SolutionsNewsApr.29,2025

-

Heavy-Duty Jackhammers for Construction Work Powerful & Portable Electric Demolition ToolsNewsApr.29,2025

-

High-Strength Fiberglass Flanges FRP Blind & Custom Flange SolutionsNewsApr.28,2025

-

Fiberglass Pipe Flanges High-Pressure & Corrosion-Resistant SolutionsNewsApr.28,2025

-

FRP Fuel Tanks Durable Fiberglass & PP Composite Fuel Storage SolutionsNewsApr.28,2025

-

FRP Trough Covers Durable Industrial Protective SolutionsNewsApr.28,2025