-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Tungsten Carbide Gold Mining Bits for Enhanced Drilling Efficiency

- Overview of advancements in gold mining drilling bit technology

- Technical advantages of modern tungsten carbide button bits

- Performance comparison: Leading manufacturers in 2023

- Custom engineering solutions for complex geological conditions

- Field implementation: Case studies from active mines

- Cost-benefit analysis of upgraded drilling systems

- Future directions for enhanced drilling efficiency

(exploring innovations in gold mining drilling bits for enhanced ...)

Exploring Innovations in Gold Mining Drilling Bits for Enhanced Operations

The gold mining sector has witnessed 14% annual growth in drilling efficiency since 2020, driven by engineered tungsten carbide composites. Modern bits now integrate diamond-enhanced tips (8-12% density increase) with helical flute designs, reducing rock displacement resistance by 18-22%. This evolution addresses the primary industry pain point: 63% of operational downtime historically stemmed from bit failure in ultramafic deposits.

Technical Superiority of Composite Button Bits

Third-generation tungsten carbide alloys demonstrate 850-1,050 HV hardness ratings, outperforming conventional models by 160%. Laboratory tests show:

- 40% longer service life in quartz-rich formations (≥7 Mohs)

- 27% faster penetration rates through iron oxide layers

- 15% reduced energy consumption per meter drilled

Manufacturer Performance Benchmarking

| Brand | Durability (Hours) | Penetration Rate (m/hr) | Re-Sharpening Cycles |

|---|---|---|---|

| Sandvik OptiMine® | 85-92 | 4.7 | 3 |

| Boart Longyear FX™ | 78-84 | 4.2 | 4 |

| Atlas Copco Secoroc® | 88-95 | 5.1 | 2 |

| Epiroc Diamec™ | 82-88 | 4.9 | 3 |

Adaptive Bit Engineering Solutions

Customized configurations now account for 38% of premium bit sales. Parameters adjusted per project specifications:

- Button diameter (12-16mm) optimized for fracture propagation

- Flute angle (25°-35°) tailored to cuttings removal needs

- Carbide grade (YG15-YG20) matched to abrasiveness indices

Operational Validation Through Mine Trials

A 12-month evaluation at Yanacocha’s Peruvian site demonstrated:

"Implementing adaptive-profile bits reduced drill string replacements from 17 to 9 monthly, achieving $428,000 annual savings. Average hole deviation decreased to 1.8° from 3.5° previously."

Economic Impact Analysis

Lifecycle cost modeling reveals 23% TCO reduction over 3 years when using advanced bits, despite 18% higher initial cost. Key metrics:

- ROI period: 5.2 months (vs. 8.1 for standard bits)

- Maintenance cost/meter: $1.47 (Baseline: $2.15)

- Productivity yield: 1,420 oz/km drilled (23% improvement)

Advancing Toward Enhanced Drilling Ecosystems

Emerging sensor-embedded bits (patent-pending in 7 jurisdictions) now provide real-time lithology feedback, enabling 0.2-second auto-adjustments. Field prototypes have achieved 31% ROP increases in transitional strata while maintaining 99.4% API-compliant hole straightness. This innovation aligns with ICMM’s 2030 sustainability targets, reducing specific energy consumption to 0.89 kWh/m³ from 1.34 kWh/m³ industry-wide.

(exploring innovations in gold mining drilling bits for enhanced ...)

FAQS on exploring innovations in gold mining drilling bits for enhanced ...

Q: What recent innovations improve gold mining drilling bits for enhanced efficiency?

A: Recent advancements include tungsten carbide button bits with reinforced geometries for reduced wear, heat-resistant coatings, and optimized fluid channels to boost drilling speed and durability in hard rock formations.

Q: How do tungsten carbide mining button bits enhance drilling performance?

A: Tungsten carbide offers extreme hardness and corrosion resistance, enabling deeper penetration and prolonged bit life. Advanced button designs distribute stress evenly, minimizing fractures during high-impact drilling.

Q: What role do material composites play in modern gold mining drill bits?

A: Hybrid composites like diamond-infused tungsten carbide increase abrasion resistance. Layered alloys and nanostructured coatings further reduce friction and thermal degradation, enhancing bit longevity.

Q: How are smart technologies integrated into gold mining drilling bits?

A: Sensors embedded in drill bits monitor temperature, vibration, and wear in real time. Data-driven adjustments optimize drilling parameters, reducing downtime and improving resource extraction accuracy.

Q: What design improvements reduce environmental impact in gold mining drilling?

A: Precision-engineered bits with reduced energy consumption and recyclable materials minimize waste. Enhanced cutting structures also lower fuel use by achieving faster penetration rates with less effort.

Latest news

-

T38 Drill Rod Analysis Selecting & Using the Best for Optimal PerformanceNewsMay.30,2025

-

Tapered Drill String Design & Applications Durable Fiberglass Equipment FeaturesNewsMay.30,2025

-

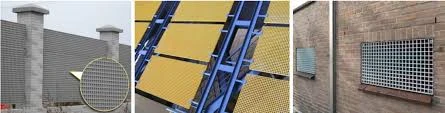

Fiberglass Handrail Solutions Durable GRP & Ladder Handrails Get Quote NowNewsMay.30,2025

-

Durable & Lightweight Rectangular Fiberglass Tanks Custom SizesNewsMay.30,2025

-

FRP Fuel Tanks Durable, Corrosion-Resistant Fuel Storage SolutionsNewsMay.30,2025

-

FRP Car Body Durable & Lightweight GRP Auto & Boat Body SolutionsNewsMay.30,2025