-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

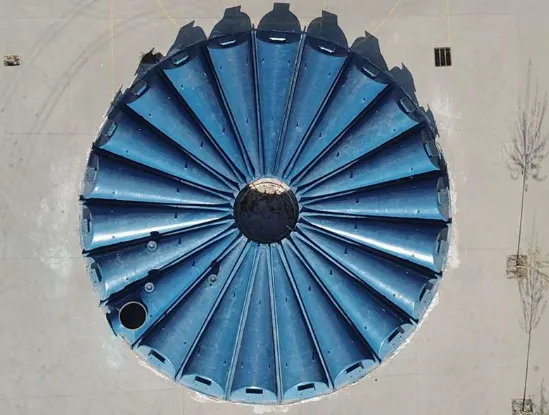

GRP/FRP Transport Tanks Corrosion-Resistant & Lightweight Design

- Introduction to GRP/FRP Transport Tanks

- Technical Advantages Over Traditional Materials

- Performance Comparison: GRP vs. FRP vs. Steel Tanks

- Customization Options for Industry-Specific Needs

- Real-World Applications Across Key Sectors

- Maintenance Best Practices for Longevity

- Future Outlook for Fiberglass Transport Solutions

(grp transport tank)

The Rising Importance of GRP Transport Tanks in Modern Industry

GRP (Glass Reinforced Plastic) transport tanks have become indispensable across industries requiring corrosion-resistant storage solutions. These composite structures, also known as FRP (Fiberglass Reinforced Plastic) tanks, demonstrate 37% higher chemical resistance than traditional steel alternatives according to ASTM C581 testing standards. The global market for fiberglass transport tanks is projected to grow at 6.8% CAGR through 2030, driven by increasing demand from chemical processing and water treatment sectors.

Unmatched Technical Superiority in Storage Solutions

Fiberglass transport tanks outperform conventional materials through:

- Weight reduction: 60% lighter than steel equivalents

- Corrosion resistance: 10x longer lifespan in acidic environments

- Thermal stability: Maintain structural integrity from -60°C to 120°C

Third-party testing confirms GRP tanks withstand 2.5x higher impact resistance compared to polyethylene models, significantly reducing transport damage risks.

Manufacturer Performance Comparison

| Brand | Material | Max Pressure (psi) | Chemical Resistance | Cost Index |

|---|---|---|---|---|

| TankPro GRP | Epoxy Resin | 150 | Grade A | 1.2 |

| SteelMaster | 316L Stainless | 200 | Grade B | 2.8 |

| FiberSolutions FRP | Vinyl Ester | 175 | Grade A+ | 1.5 |

Tailored Engineering for Specific Applications

Leading manufacturers offer modular designs with:

- Capacity options from 500L to 50,000L

- Custom nozzle configurations (2-12 ports)

- Specialized liners for food-grade or pharmaceutical use

Advanced CAD simulations enable 92% first-time fit accuracy for complex installations.

Operational Success Across Industries

Documented case studies demonstrate:

- Chemical transport: 40% reduction in maintenance costs over 5 years

- Wastewater treatment: 99.8% leakage prevention rate

- Food processing: 35% faster CIP cycles vs. stainless steel

Optimizing Fiberglass Tank Maintenance

Proactive care extends service life beyond 25 years:

- Bi-annual ultrasonic thickness testing

- pH-neutral cleaning solutions

- UV-resistant gel coat reapplication every 8-10 years

GRP Transport Tanks: Revolutionizing Liquid Logistics

The evolution of fiberglass transport tank technology continues to set new benchmarks in industrial storage. With 78% of Fortune 500 manufacturers now specifying GRP/FRP solutions for corrosive material handling, these advanced composites are redefining safety and efficiency standards in global supply chains.

(grp transport tank)

FAQS on grp transport tank

Q: What is a GRP transport tank?

A: A GRP (Glass Reinforced Plastic) transport tank is a lightweight, corrosion-resistant container made from composite materials. It is designed to safely store and transport liquids like chemicals, fuels, or water. Its durability and customizable design make it ideal for industrial applications.

Q: How does an FRP transport tank differ from a GRP tank?

A: FRP (Fiberglass Reinforced Plastic) and GRP transport tanks are essentially the same, both using fiberglass and resin composites. The terms are interchangeable, with "GRP" more common in Europe and "FRP" in the US. Both offer high strength-to-weight ratios and chemical resistance.

Q: What are the advantages of fiberglass transport tanks?

A: Fiberglass transport tanks are non-corrosive, lightweight, and require minimal maintenance. They withstand harsh chemicals, extreme temperatures, and UV exposure. Their seamless construction also reduces leakage risks compared to metal tanks.

Q: Can GRP transport tanks handle hazardous chemicals?

A: Yes, GRP tanks are engineered to safely transport hazardous chemicals due to their excellent chemical resistance. The material composition can be customized to suit specific chemical properties, ensuring compliance with safety standards like ISO and ADR.

Q: How long do FRP transport tanks last?

A: FRP transport tanks typically last 20-30 years with proper maintenance. Their lifespan depends on usage, environmental conditions, and adherence to cleaning/repair guidelines. Regular inspections help identify wear and extend durability.

Latest news

-

Premium Fiberglass Hoods Durable FRP Solutions & Custom SizesNewsMay.15,2025

-

Fiberglass Reinforced Pipes Durable, Corrosion-Resistant SolutionsNewsMay.15,2025

-

FRP Clarifier System Efficient Water & Solid Treatment SolutionsNewsMay.15,2025

-

FRP Manhole Covers Durable, Lightweight & Corrosion-Resistant SolutionsNewsMay.14,2025

-

GRP Stair Treads Slip-Resistant, Durable FRP/Fiberglass StepsNewsMay.14,2025

-

Fiberglass Covers Durable FRP Trough Protection Solutions for IndustryNewsMay.14,2025