-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mrz . 07, 2025 05:47

Back to list

Steps

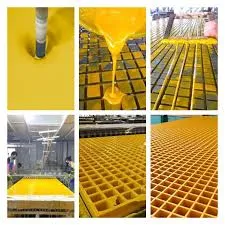

Fiberglass demisters have emerged as essential components in various industrial processes, gaining recognition for their unparalleled efficiency in gas-liquid separation. With the increased demand for cleaner industrial operations, understanding the intricacies of fiberglass demisters can significantly enhance operational quality and environmental compliance.

Trustworthiness, meanwhile, is built over years of delivering consistent, reliable, and effective solutions. A trustworthy manufacturer of fiberglass demisters invests in rigorous quality checks and testing procedures, ensuring each unit meets the stringent performance criteria before reaching clients. Testimonials from longstanding clients who have reaped operational benefits from these demisters further underline the trustworthiness of a company. Longevity in partnerships and repeat business are often the most telling indicators of a trusted brand within this niche. The experience of integrating fiberglass demisters into existing systems can often seem daunting, yet it is a critical step for enhancing efficiency. For those willing to invest in the right expertise, the process can be seamless and rewarding. Specialists should be consulted to carry out a comprehensive systems analysis to identify the optimal integration points and ensure compatibility with the existing infrastructure. Not only does this maximize demister performance, but it also minimizes potential operational disruptions. For best results in terms of product longevity and performance, maintenance of fiberglass demisters is paramount. Regular inspections and cleanings are necessary to prevent clogging of the mesh and preserve its separation capabilities. Experienced users of these demisters recommend developing a regular maintenance schedule tailored to the specific operational conditions of the facility. This practice greatly extends the life of the demisters and secures their operational efficiency, underscoring the importance of experience and expertise in maximizing product effectiveness. In conclusion, fiberglass demisters represent a confluence of modern engineering and industrial necessity, addressing the critical need for efficient gas-liquid separation. By leveraging the product's strengths, backed by the authoritative and trustworthy expertise of leading manufacturers, industries can achieve better environmental outcomes and operational efficiencies. Whether it's through skilled product integration, ongoing maintenance, or continuous product innovation, fiberglass demisters stand out as a vital component in contemporary industrial processes, illustrating the profound impact that expertly crafted solutions can have on both business success and environmental stewardship.

Trustworthiness, meanwhile, is built over years of delivering consistent, reliable, and effective solutions. A trustworthy manufacturer of fiberglass demisters invests in rigorous quality checks and testing procedures, ensuring each unit meets the stringent performance criteria before reaching clients. Testimonials from longstanding clients who have reaped operational benefits from these demisters further underline the trustworthiness of a company. Longevity in partnerships and repeat business are often the most telling indicators of a trusted brand within this niche. The experience of integrating fiberglass demisters into existing systems can often seem daunting, yet it is a critical step for enhancing efficiency. For those willing to invest in the right expertise, the process can be seamless and rewarding. Specialists should be consulted to carry out a comprehensive systems analysis to identify the optimal integration points and ensure compatibility with the existing infrastructure. Not only does this maximize demister performance, but it also minimizes potential operational disruptions. For best results in terms of product longevity and performance, maintenance of fiberglass demisters is paramount. Regular inspections and cleanings are necessary to prevent clogging of the mesh and preserve its separation capabilities. Experienced users of these demisters recommend developing a regular maintenance schedule tailored to the specific operational conditions of the facility. This practice greatly extends the life of the demisters and secures their operational efficiency, underscoring the importance of experience and expertise in maximizing product effectiveness. In conclusion, fiberglass demisters represent a confluence of modern engineering and industrial necessity, addressing the critical need for efficient gas-liquid separation. By leveraging the product's strengths, backed by the authoritative and trustworthy expertise of leading manufacturers, industries can achieve better environmental outcomes and operational efficiencies. Whether it's through skilled product integration, ongoing maintenance, or continuous product innovation, fiberglass demisters stand out as a vital component in contemporary industrial processes, illustrating the profound impact that expertly crafted solutions can have on both business success and environmental stewardship.

Next:

Related Products