-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

2월 . 17, 2025 13:57

Back to list

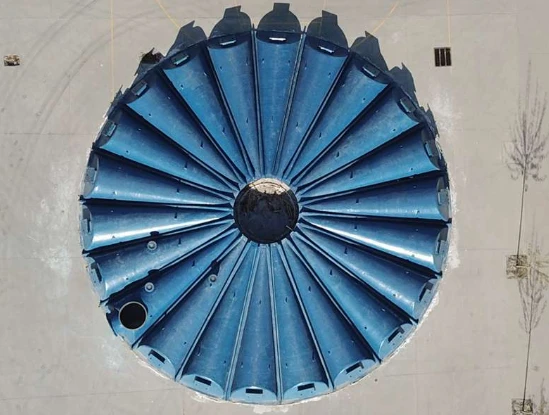

Insulation Tanks

Home improvement projects and industrial applications often demand materials that combine strength, versatility, and customization. Fiberglass customized fittings are emerging as a top choice for projects where traditional materials like metal and plastic fall short. The qualities of fiberglass make it particularly suitable for a vast array of applications, delivering unmatched performance in terms of durability, flexibility, and corrosion resistance.

From an expertise standpoint, the manufacturing process of fiberglass fittings offers distinct advantages. Expertise in this field hinges on a firm grasp of both the raw materials and the precise engineering techniques required to manipulate them. The intricacies involved in the layering of glass fibers with resin material to achieve optimal strength and flexibility calls for a high level of technical skill and knowledge. Manufacturers with a proven track record and considerable experience in crafting fiberglass products ensure that the final output meets stringent quality standards, providing assurance of their reliability and engineering excellence. Expertise alone, however, isn't enough; authoritativeness in the fiberglass industry is equally critical. Industry leaders leverage years of research and development to push the boundaries of what fiberglass can achieve. By investing in state-of-the-art machinery and adhering to global certification standards, these authoritative voices set benchmarks that elevate the entire industry. Their authoritative stance is reinforced through vast portfolios of successful projects across diverse industries—from aerospace to renewable energy—demonstrating their leadership and innovation in applying fiberglass solutions. Trustworthiness in fiberglass customized fittings emerges from transparent business practices and customer-centric service. A trustworthy provider will prioritize clear communication, timely delivery, and responsive after-sales support, ensuring that clients feel valued and understood throughout the purchase process. Additionally, offering warranties and quality assurances build trust, as they signify confidence in the product's longevity and performance. Testimonials from satisfied customers and repeat business serve as testimonials to a brand's dedication to quality and its integrity. As fiberglass customized fittings continue to gain traction across various sectors, their value proposition becomes increasingly apparent. They offer not just a material solution, but a comprehensive approach to modern engineering challenges. By marrying customization with structural strength and environmental resilience, fiberglass products are setting new standards for what industries can expect from advanced material technology. As more projects turn to this versatile material, the craftsmanship made possible through fiberglass is set to redefine the possibilities of robust, innovative design in the modern world.

From an expertise standpoint, the manufacturing process of fiberglass fittings offers distinct advantages. Expertise in this field hinges on a firm grasp of both the raw materials and the precise engineering techniques required to manipulate them. The intricacies involved in the layering of glass fibers with resin material to achieve optimal strength and flexibility calls for a high level of technical skill and knowledge. Manufacturers with a proven track record and considerable experience in crafting fiberglass products ensure that the final output meets stringent quality standards, providing assurance of their reliability and engineering excellence. Expertise alone, however, isn't enough; authoritativeness in the fiberglass industry is equally critical. Industry leaders leverage years of research and development to push the boundaries of what fiberglass can achieve. By investing in state-of-the-art machinery and adhering to global certification standards, these authoritative voices set benchmarks that elevate the entire industry. Their authoritative stance is reinforced through vast portfolios of successful projects across diverse industries—from aerospace to renewable energy—demonstrating their leadership and innovation in applying fiberglass solutions. Trustworthiness in fiberglass customized fittings emerges from transparent business practices and customer-centric service. A trustworthy provider will prioritize clear communication, timely delivery, and responsive after-sales support, ensuring that clients feel valued and understood throughout the purchase process. Additionally, offering warranties and quality assurances build trust, as they signify confidence in the product's longevity and performance. Testimonials from satisfied customers and repeat business serve as testimonials to a brand's dedication to quality and its integrity. As fiberglass customized fittings continue to gain traction across various sectors, their value proposition becomes increasingly apparent. They offer not just a material solution, but a comprehensive approach to modern engineering challenges. By marrying customization with structural strength and environmental resilience, fiberglass products are setting new standards for what industries can expect from advanced material technology. As more projects turn to this versatile material, the craftsmanship made possible through fiberglass is set to redefine the possibilities of robust, innovative design in the modern world.

Next:

Related Products