-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 16, 2025 03:04

Back to list

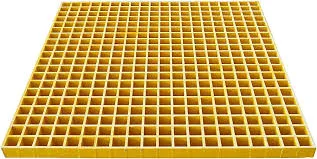

corrosion resistant frp

Corrosion-resistant FRP (Fiber Reinforced Plastic) is revolutionizing industries where durability and longevity are paramount. As industries increasingly demand materials that not only promise robust performance but also resist the corrosive effects of harsh environments, FRP emerges as an unstoppable force due to its exceptional attributes.

In wastewater treatment facilities, where chemical corrosion can dramatically shorten the lifespan of traditional materials, FRP stands as a beacon of endurance. Its strength-to-weight ratio outperforms many metals, and its non-conductive properties further enhance its utility in environments where safety is as critical as performance. These properties underscore the material’s authority within the industrial sector, as trust in FRP's reliability grows with each successful application. The advanced design flexibility of FRP offers another edge. Custom shapes, sizes, and configurations are achievable without compromising on performance or durability, allowing for innovative designs that were previously inconceivable with other materials. This adaptability extends the scope of FRP's applications, providing an authoritative voice in both existing industries and emerging markets where corrosion resistance is pivotal. Ultimately, the adoption of corrosion-resistant FRP is an investment in quality and longevity. With decades of authoritative research and practical experience reinforcing its benefits, FRP products continue to earn the trust and respect of industries across the globe. The expertise involved in each step of its creation—from conceptual design to practical implementation—demonstrates a commitment to solving corrosion challenges definitively. For those seeking corrosion-resistant solutions, the choice of FRP is not just a decision but a commitment to adopting the best in durability and design. With unique experiences endorsing its effectiveness, FRP stands as the epitome of reliable, forward-thinking material technology.

In wastewater treatment facilities, where chemical corrosion can dramatically shorten the lifespan of traditional materials, FRP stands as a beacon of endurance. Its strength-to-weight ratio outperforms many metals, and its non-conductive properties further enhance its utility in environments where safety is as critical as performance. These properties underscore the material’s authority within the industrial sector, as trust in FRP's reliability grows with each successful application. The advanced design flexibility of FRP offers another edge. Custom shapes, sizes, and configurations are achievable without compromising on performance or durability, allowing for innovative designs that were previously inconceivable with other materials. This adaptability extends the scope of FRP's applications, providing an authoritative voice in both existing industries and emerging markets where corrosion resistance is pivotal. Ultimately, the adoption of corrosion-resistant FRP is an investment in quality and longevity. With decades of authoritative research and practical experience reinforcing its benefits, FRP products continue to earn the trust and respect of industries across the globe. The expertise involved in each step of its creation—from conceptual design to practical implementation—demonstrates a commitment to solving corrosion challenges definitively. For those seeking corrosion-resistant solutions, the choice of FRP is not just a decision but a commitment to adopting the best in durability and design. With unique experiences endorsing its effectiveness, FRP stands as the epitome of reliable, forward-thinking material technology.

Next:

Related Products