-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 05, 2025 02:20

Back to list

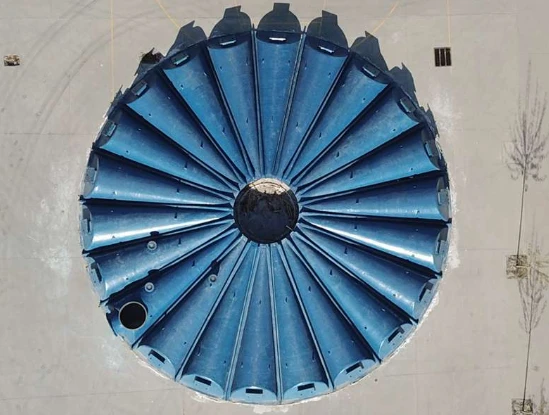

corrosion solution

Corrosion is a pervasive challenge faced by industries worldwide, costing billions in maintenance and repair each year. This persistent issue demands innovative solutions tailored specifically to prevent the degradation of metals and extend the lifecycle of industrial machinery and infrastructure. The optimal corrosion solution not only curtails damage but also significantly contributes to safety and performance efficiency.

Authoritativeness in the field of corrosion science is established through a robust body of research and a history of successful applications. Firms that excel in offering corrosion solutions typically host teams of seasoned scientists and engineers specialized in surface engineering, chemical analysis, and environmental sciences. These teams develop tailored solutions, ensuring each project meets stringent safety and environmental standards. Their authoritative stance is bolstered by credentials, patents, and publications in recognized journals, providing a benchmark for quality and reliability. Trustworthiness is arguably the most critical aspect when selecting corrosion solutions. A transparent approach towards product testing, efficacy reports, and client testimonials can provide potential clients with confidence in the solution's effectiveness. Reputable companies adhere to international standards such as ISO 12944, which outlines the best practices in corrosion protection of steel structures. Verified field tests and third-party certifications further enhance the credibility and dependability of a corrosion solution provider. Innovations in corrosion technology continually evolve, and staying informed on the latest advancements is key for any industry reliant on metal infrastructure. For industries seeking sustainable and cost-effective solutions, emerging technologies such as self-healing coatings and nano-engineered materials offer exciting prospects. These futuristic approaches promise to revolutionize corrosion management by not only preventing deterioration but also actively repairing initial damage. In conclusion, the creation of a unique, effective corrosion solution is dependent on a thorough understanding of each component's role—from materials science and engineering expertise to environmental considerations and quality assurances. Companies that adopt such a holistic approach are better equipped to safeguard their investments while ensuring the safety and operational efficiency of their assets. The next step for industry leaders is to integrate these advanced solutions into their maintenance regimes, thereby forging a future where corrosion is not merely managed, but predictably controlled.

Authoritativeness in the field of corrosion science is established through a robust body of research and a history of successful applications. Firms that excel in offering corrosion solutions typically host teams of seasoned scientists and engineers specialized in surface engineering, chemical analysis, and environmental sciences. These teams develop tailored solutions, ensuring each project meets stringent safety and environmental standards. Their authoritative stance is bolstered by credentials, patents, and publications in recognized journals, providing a benchmark for quality and reliability. Trustworthiness is arguably the most critical aspect when selecting corrosion solutions. A transparent approach towards product testing, efficacy reports, and client testimonials can provide potential clients with confidence in the solution's effectiveness. Reputable companies adhere to international standards such as ISO 12944, which outlines the best practices in corrosion protection of steel structures. Verified field tests and third-party certifications further enhance the credibility and dependability of a corrosion solution provider. Innovations in corrosion technology continually evolve, and staying informed on the latest advancements is key for any industry reliant on metal infrastructure. For industries seeking sustainable and cost-effective solutions, emerging technologies such as self-healing coatings and nano-engineered materials offer exciting prospects. These futuristic approaches promise to revolutionize corrosion management by not only preventing deterioration but also actively repairing initial damage. In conclusion, the creation of a unique, effective corrosion solution is dependent on a thorough understanding of each component's role—from materials science and engineering expertise to environmental considerations and quality assurances. Companies that adopt such a holistic approach are better equipped to safeguard their investments while ensuring the safety and operational efficiency of their assets. The next step for industry leaders is to integrate these advanced solutions into their maintenance regimes, thereby forging a future where corrosion is not merely managed, but predictably controlled.

Related Products